Processing plasma cut parts doesn’t have to be hard. Utilize these tips to save time and money on your processing operations.

Read MoreWant to learn more about waterjet, oxy-fuel, and plasma cutting systems? Our manufacturing blog covers everything you need to know.

Stainless Steel Cutting Starter Tips

Cutting stainless steel can be challenging without the right equipment and processes in place. Set yourself up for success with these tips.

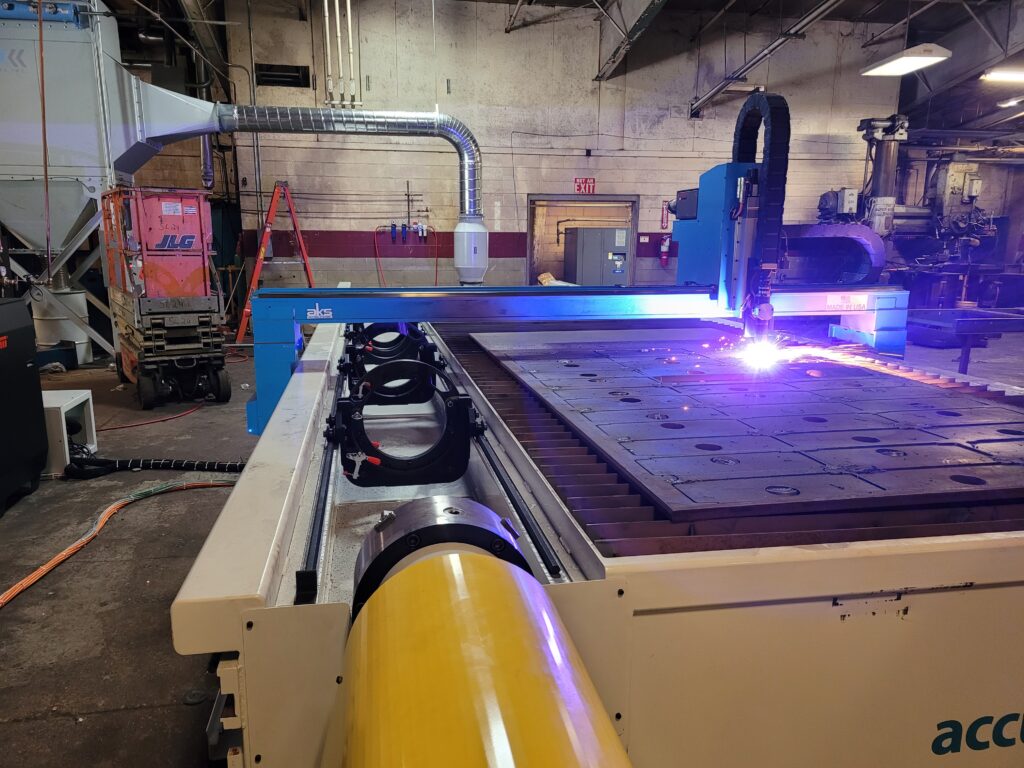

Read MoreExpand Your Business Opportunities with the AKS tube-kut

The AKS tube-kut is a valuable asset for any fabrication shop looking to stay ahead in a competitive market. Learn more here.

Read MoreWebster Industries Increases Efficiency and Accuracy with AKS’ CNC Cutting Machines

Webster Industries increased efficiency and accuracy by switching to CNC cutting machines from AKS. Learn more here.

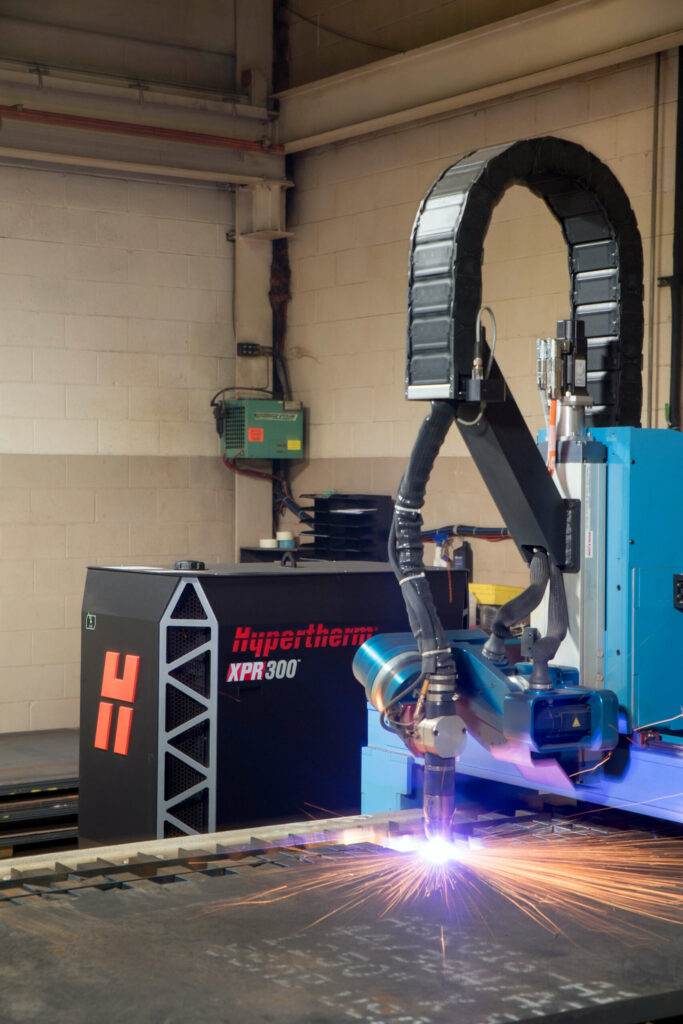

Read MoreRobo-kut Your Plasma Beveling Solution

The AKS Cutting Systems robo-kut can help you increase efficiency and reduce costs in your cutting operations. Learn more here.

Read MoreWesLor Enterprises Increases Efficiency with Suite of AKS Products

Explore WesLor’s journey to expedited plasma bevel operations and streamlined processes for unmatched service.

Read MoreThe Future of Plasma Metal Cutting Technology

Discover the future of plasma metal cutting — where automation meets an increased emphasis on the recycling sector.

Read MoreMetalworking Shop Optimizes Carriage Bolt Hole Creation with AKS Cutting Systems’ robo-kut

A manufacturer in Pennsylvania optimized their carriage bolt hole creation using AKS Cutting Systems’ robo-kut attachment. Learn more here.

Read MoreJorgensen Steel Chooses Plasma Over Laser for Improved Cutting Performance

Jorgensen Steel chose a plasma cutting machine over laser cutting equipment. Why? Find out from our in-depth case study.

Read More5 Tips for Effective Oxy-Fuel Cutting Operations

Ensure Quality Cuts with Tips from AKS Cutting Systems Oxy-fuel cutting systems are designed to provide precise, efficient cuts for a variety of industries, including the metal fabrication, automotive, and aerospace sectors, among others. These industries require accurate parts to …

Read MoreThe Importance of Maintaining Consistent CNC Plasma Cutting Gas Pressure

When operating a CNC plasma cutting system, it’s imperative to use consistent gas pressure to ensure the highest quality cuts. Additionally, ensuring a steady plasma cutting gas pressure may help extend the life of your torch. But, how do you …

Read MoreOxy-fuel Cutting Advantages and Disadvantages: Is it Right for Your Business?

How to Determine if Oxy-fuel Cutting is Right for Your Business In its simplest form, oxy-fuel cutting is a thermal cutting process that uses oxygen and fuel gas to cut through material. Oxy-fuel cutting systems have a wide range of …

Read More