How AKS’ robo-kut Streamlined Carriage Bolt Holes for a Pennsylvania Manufacturer

When a long-term AKS client faced an issue creating carriage bolt holes, the company turned to AKS for help. The facility was using punches and CNC machine centers to manufacture carriage bolt holes in parts; however, this process was time-consuming and put unnecessary strain on the punch machine. With aging punch equipment, the customer couldn’t afford to keep using it at its current rate. The answer to this problem came via AKS’ robo-kut attachment.

The AKS robo-kut Delivers a Superior Solution

When the Pennsylvania metalworking shop reached out to AKS with its problem, we promptly dispatched representatives to the facility to showcase how the robo-kut attachment could optimize carriage bolt-hole creation.

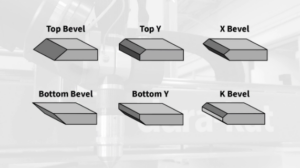

Types of bevel cuts reliably cut by the AKS robo-kut

As the most powerful option in the industry, the robo-kut plasma cutting five-axis bevel head was more than perfect for this need. It can cut +/- 45 degrees for A, V, K, X, top-Y, and bottom-Y style bevel cuts for weld prep applications, countersinks, chamfers, and more. It proved to be the perfect solution for the company’s challenge, because of its capability to create 0.5:1 ratio hole diameters.

The main issue the manufacturer had was the need to put a 0.5-inch bolt into a 1-inch plate. Previously, this type of challenge could only be met through the combination of a punch and CNC machining center. However, the AKS team showed it was possible for the robo-kut to meet this need, and at a cheaper price than buying another punch. Instead, the company could use the punch only when absolutely necessary, and delay the need to purchase another expensive machine.

The AKS robo-kut Slashes Turnaround Times and Optimizes Costs

With a 0.003-inch motion accuracy and repeatability to 0.001-inch, the robo-kut is able to deliver high-quality carriage bolt holes at a fraction of the price. After just one week of installation and general training, the metalworking shop was up and running, fabricating parts for their customers at a much faster rate than before.

This remarkable enhancement not only demonstrates the robo-kut’s efficiency, but also underscores its swift integration into the manufacturing workflow. With heightened speed and accuracy, our client is now positioned to meet customer demands more promptly, showcasing the tangible impact of AKS’ cutting-edge technology on their operational efficiency and overall productivity.

About AKS Cutting Systems

AKS Cutting Systems is a leading provider of CNC plasma and waterjet cutting machines. As a fourth-generation, family-owned and operated company, AKS has a strong reputation for durability, accuracy, and reliability with thousands of installations worldwide. For sales inquiries, please contact info@AKSCuttingSystems.com.