Stan Pollack, Regional Sales Manager, is a 47-year industry veteran who began working at AKS Cutting Systems in 2001. Prior to joining AKS, he held positions with Rexnord Corp., Acme Cleveland, ACE Automation, Cyclone Industries, and then Kiffer Industries Inc., …

Read More

Want to learn more about waterjet, oxy-fuel, and plasma cutting systems? Our manufacturing blog covers everything you need to know.

GMA Garnet Group: The Difference is in the Detail

Water alone doesn’t cut into steel. The key ingredient is a granular abrasive – such as garnet – which increases a waterjet’s cutting power, slicing effortlessly into the hardest metals. The quality of the abrasive has a direct impact on …

Read More

AKS Employee Spotlight: Mike Semrau

Mike Semrau, director of AKS Cutting Systems’ Consumables Loyalty Program, is a 32-year industry veteran who knows the value of hard work and quality machines. After graduating from high school, Semrau completed a four-year apprenticeship program with a local Cleveland …

Read More

A G Equipment Improves Versatility, Precision With AKS Plasma Cutting System

Pictured: From left to right: Ed Raschen, President, AKS Dealer C4 Industrial – Jose Avila, Operator, AG Equipment. AG Equipment Co., a Broken Arrow, Oklahoma-based producer of natural gas compressor packages, purchased an AKS Cutting Systems plasma cutter in 2021 …

Read More

AKS Employee Spotlight: Dan Diamond

Dan Diamond, a service technician at AKS Cutting Systems, believes working for the company has allowed him to reach both professional and personal goals. The Northeast Ohio native, who learned CNC manufacturing at Lorain County Community College where his father …

Read More

AKS Employee Spotlight: Walt DeBiasi

Walt DeBiasi, AKS Cutting Systems regional sales manager for the southeast and north central regions, has been with the company for more than 23 years. A valued employee that is the epitome of dedication, DeBiasi saw a long-term future at …

Read More

The Importance of Regular Maintenance for Plasma Cutting Machines

When a business relies on plasma cutting machines to keep production rolling, preventive maintenance is a requirement of a successful operation. Without it, even the highest quality machine will show signs of premature wear, experience inferior cut quality and eventually …

Read More

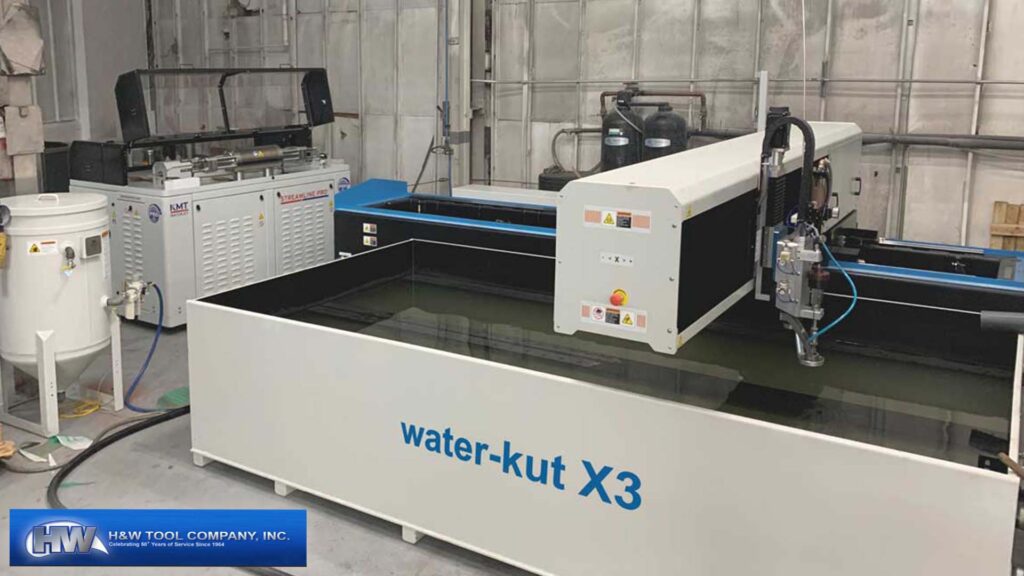

H&W Tool Sees Increased Accuracy, Efficiency with AKS Waterjet Cutting Systems

H&W Tool Co., a family-owned tool and die company that provides services to the aerospace and medical communities. When they needed new waterjet cutting tables at its plants in Ohio, New Jersey and Virginia they turned to AKS Cutting Systems.

Read More

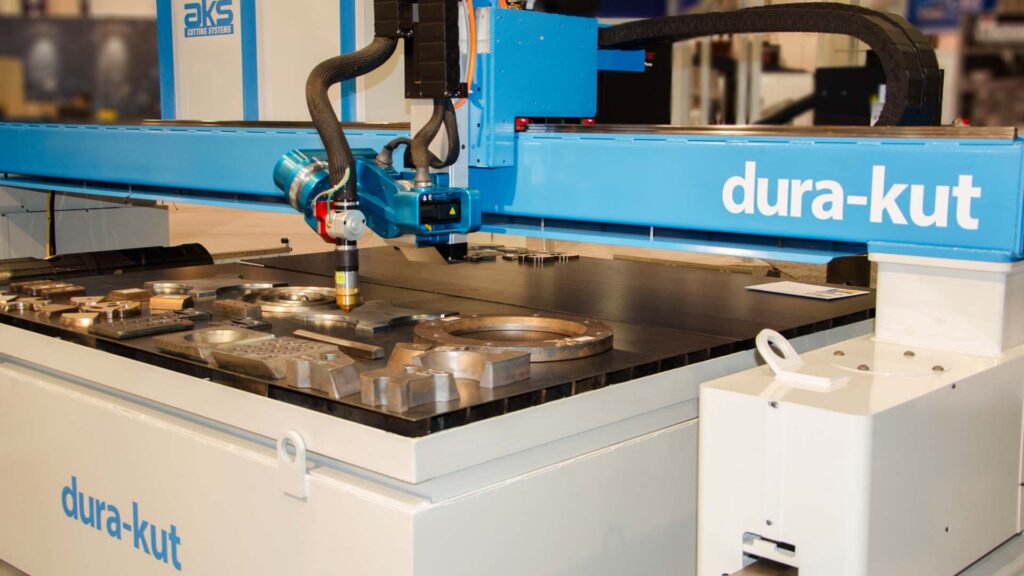

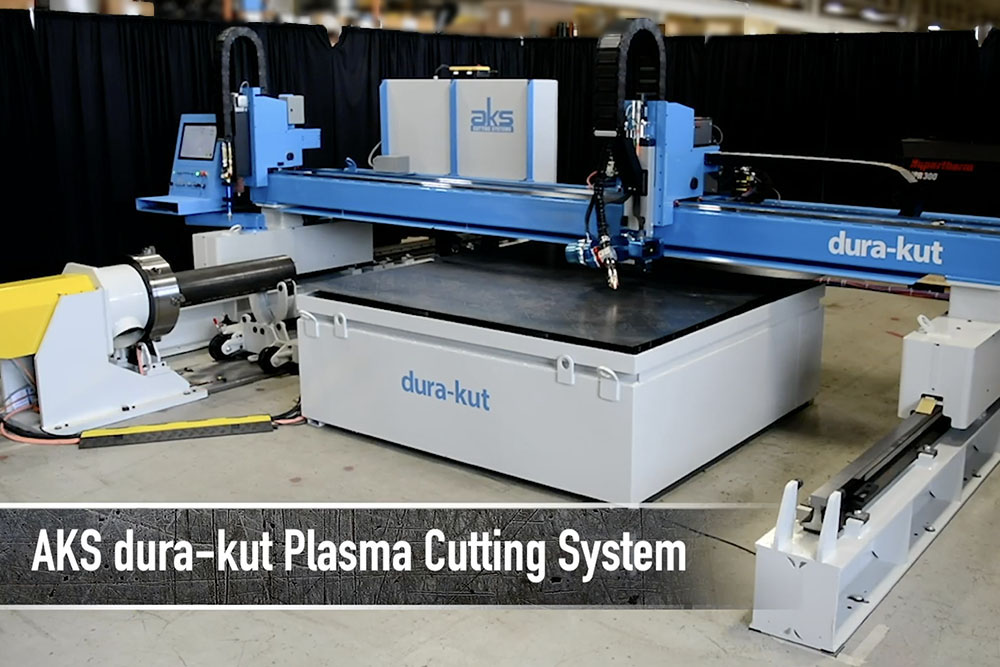

AKS dura-kut Plasma Cutting System

The dura-kut gantry-style plasma cutting system with independent table and motion system. Designed for larger and thicker plate cutting.

Read More

How to Save Costs with Efficient Use of Materials

Using a top-quality plasma cutting machine from AKS Cutting Systems offers several advantages, especially when paired with Hypertherm ProNest software and when preventive maintenance is performed at recommended intervals.

Read More

How to Ensure a Plasma Table’s Bridge is Square

Precision is one of the main advantages of plasma cutting systems, and it is important to take steps to maintain that precision in a few key areas.

Read More

The Importance of Fume and Smoke Mitigation in Plasma Cutting

In any operation using a plasma cutter, proper ventilation is vital to keeping operators safe and equipment in optimal condition. Learn more here.

Read More