Curious about CNC plasma cutting holes? The robo-kut can achieve 0.5:1 ratio holes. Learn more here.

Read MoreHow AKS Service Manager Scott Krankowski Helps Cleveland Tank and Supply CutEVERYDay

Even the best plasma cutting machine needs support from time to time. Learn how our service manager keeps them cutting.

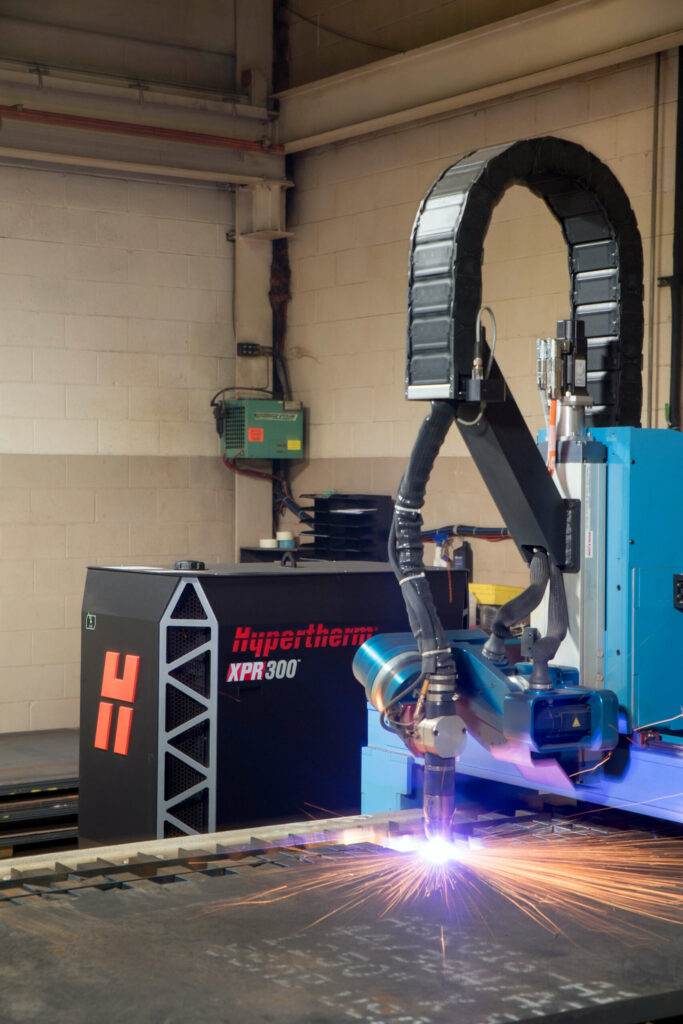

Read MoreHypertherm XPR300 vs. XPR460 Plasma Power Supplies: What’s Right for Your Business?

Don’t know whether the Hypertherm XPR460 or XPR300 is right for your application? Get all the details from the experts at AKS Cutting Systems.

Read MoreWhat is the Effect of Dry Plasma Cutting on Stainless Steel?

Questions about how dry plasma cutting stainless steel affects the HAZ? Get all the insights from the team at AKS Cutting Systems.

Read MoreWesLor Enterprises Increases Efficiency with Suite of AKS Products

Explore WesLor’s journey to expedited plasma bevel operations and streamlined processes for unmatched service.

Read MoreThe Future of Plasma Metal Cutting Technology

Discover the future of plasma metal cutting — where automation meets an increased emphasis on the recycling sector.

Read MoreMetalworking Shop Optimizes Carriage Bolt Hole Creation with AKS Cutting Systems’ robo-kut

A manufacturer in Pennsylvania optimized their carriage bolt hole creation using AKS Cutting Systems’ robo-kut attachment. Learn more here.

Read MoreJorgensen Steel Chooses Plasma Over Laser for Improved Cutting Performance

Jorgensen Steel chose a plasma cutting machine over laser cutting equipment. Why? Find out from our in-depth case study.

Read MoreThe Importance of Maintaining Consistent CNC Plasma Cutting Gas Pressure

When operating a CNC plasma cutting system, it’s imperative to use consistent gas pressure to ensure the highest quality cuts. Additionally, ensuring a steady plasma cutting gas pressure may help extend the life of your torch. But, how do you …

Read MoreLaser Cutting vs. Plasma Cutting — Choose What’s Right for Your Business

Laser and Plasma Cutting Help Drive Manufacturing Laser and plasma cutting systems are both used in the manufacturing space, easily readying metal for use across a host of industries. While similar, laser and plasma cutting systems are not interchangeable. Each …

Read MoreBest Practices for a Quality Cut

When it comes to the advantages of plasma cutting systems, users can count on versatility, speed, safety and precision, among other benefits. Each AKS Cutting Systems machine is durable, accurate and reliable, especially if regular maintenance and other basic steps …

Read More7 Benefits of the AKS Self-Cleaning System for Plasma Cutting Machines

7 Benefits of the AKS Self-Cleaning System for Plasma Cutting Machines — available as an option on the company’s accu-kut plasma cutting machine — boosts efficiency, saves time and increases workplace safety, contributing to an overall cost savings. The Self-Cleaning …

Read More