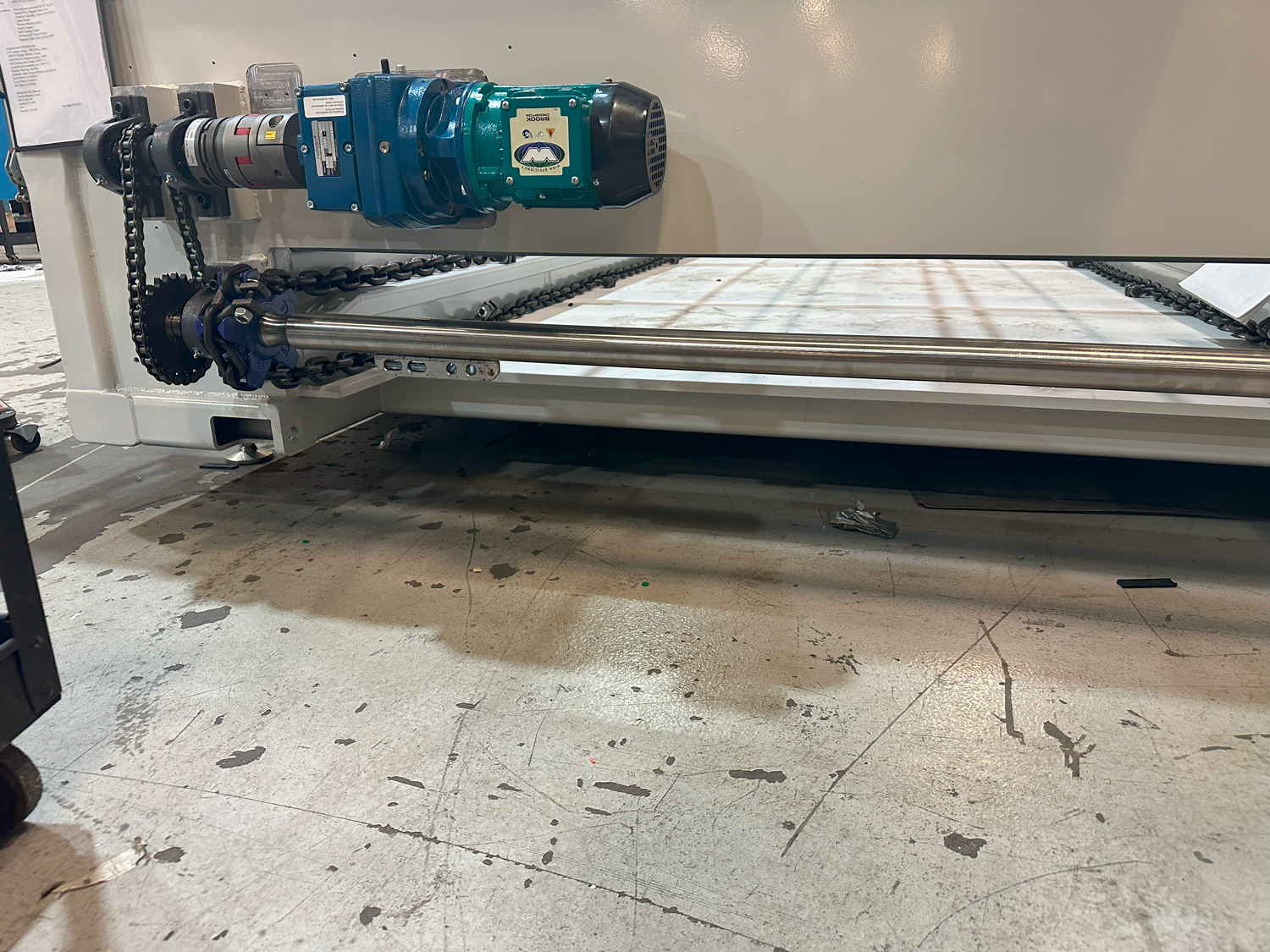

Improve Efficiency and Reduce Costs with the accu-kut Self-Cleaning System

Want easier and faster removal of debris and scrap? The AKS accu-kut model offers a self-cleaning system that can do just that. With easy part retrieval, this system results in more efficient operations and eliminates costs associated with manual cleaning. Learn more about the self-cleaning system below, or reach out to our team with questions.