Exceptional Entry-Level Plasma Cutting Starts Here

Designed as an upgraded version of the acclaimed PLASMATIC, the PLASMATIC Pro sets a new standard in entry-level CNC plasma cutting machines. It delivers exceptional performance, ease of operation, and unparalleled precision that you won’t get with competitors’ products.

The PLASMATIC Pro is highly customizable, just like all of our machines. With countless options available, you can create the perfect machine for your operation. Our team is standing by to help you find the best options for your business. Contact us today to learn what’s best for you.

Specifications

| Motion Accuracy | 0.005” per 3 feet of motion |

| Travel Speed | 1200 ipm |

| Screen Size | 19-inches |

| Max Cut Depth | 3 inches |

| Max Cut Width | Up to 6 |

| Max Cut Length | Up to 12 |

Features

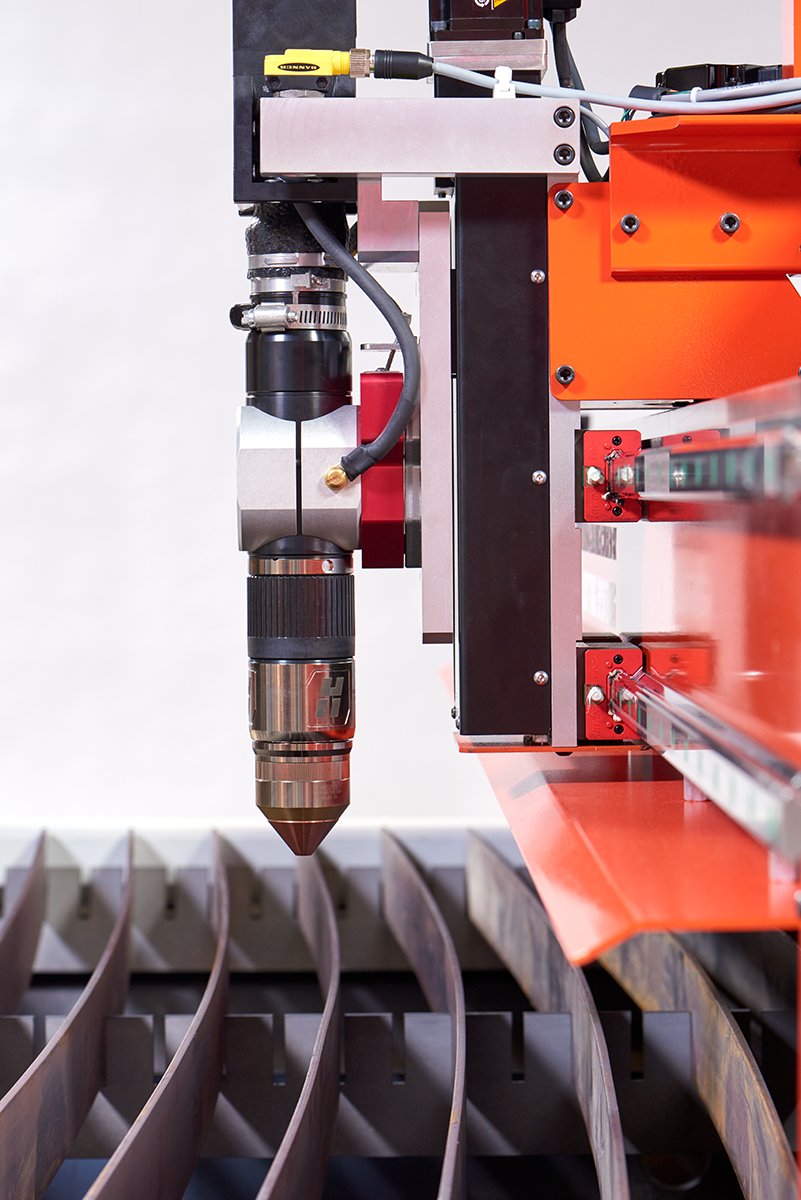

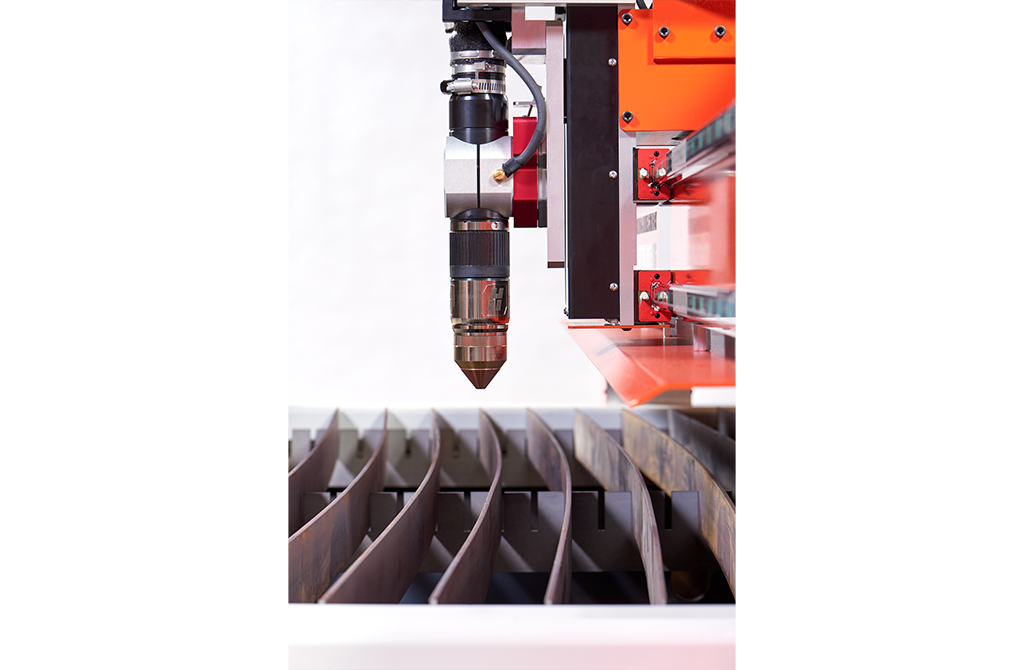

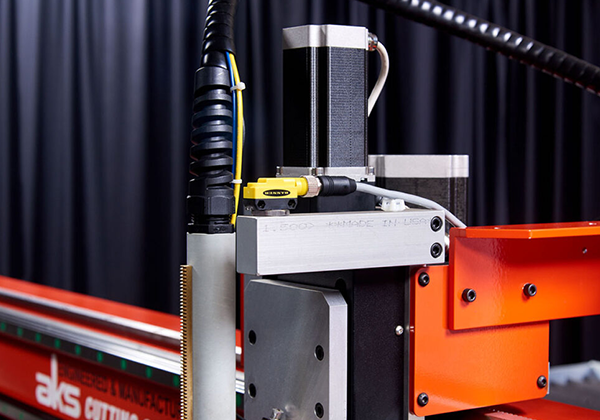

Advanced THC Lifter

Our advanced torch height control (THC) lifter helps maintain a consistent and optimal distance between the torch and workpiece. This results in precise and high-quality cuts while also protecting the torch and extending consumable life.

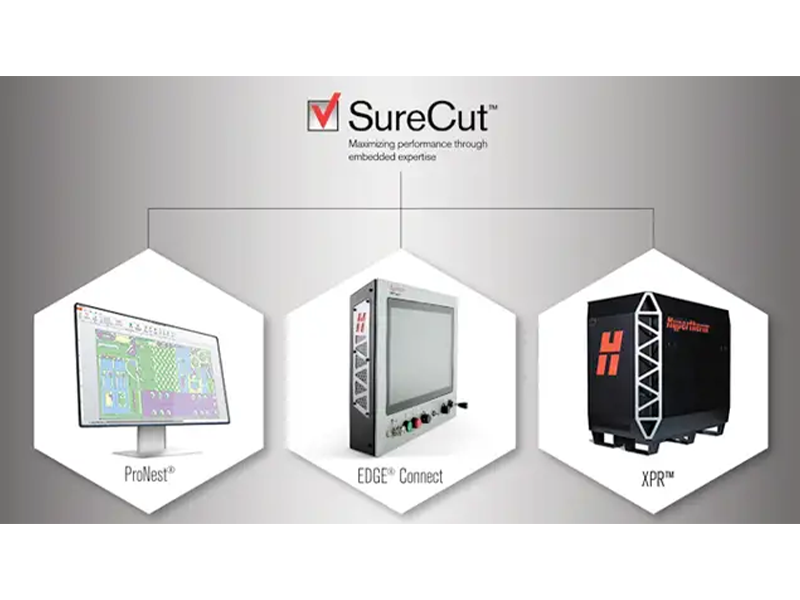

Hypertherm SureCut™ Technology

SureCut™ Technology automatically applies optimized cutting parameters, which simplifies cutting and reduces operator intervention.

Hypertherm Edge Connect CNC Controller

The Edge Connect CNC controller enhances overall system reliability, improves cut quality, and increases productivity for your operation.

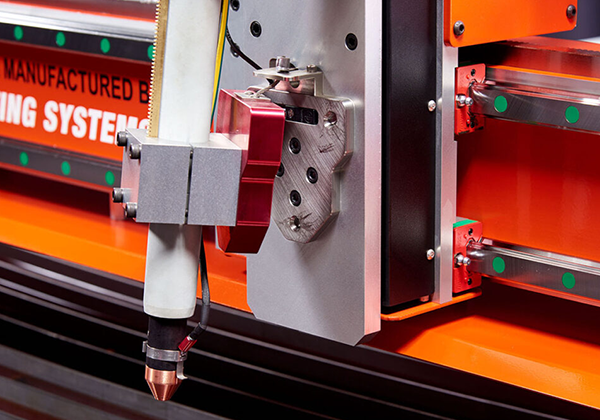

Standard Hy-Definition Torch

With a hy-definition torch, you can achieve high-quality, high-precision cuts in various metal thicknesses.

Torch Height Control (THC) Lifter

Utilizing Hypertherm Sensor technology, the torch height control lifter automatically controls torch height during the cutting process. It’s also fitted with a servo driven ball screw with arc voltage control system. This gives you more efficiency and safety in your operation.

Unitized Construction

Rigid and robust design ensures strength, productivity, and reliability, with performance and durability far exceeding less capable models.

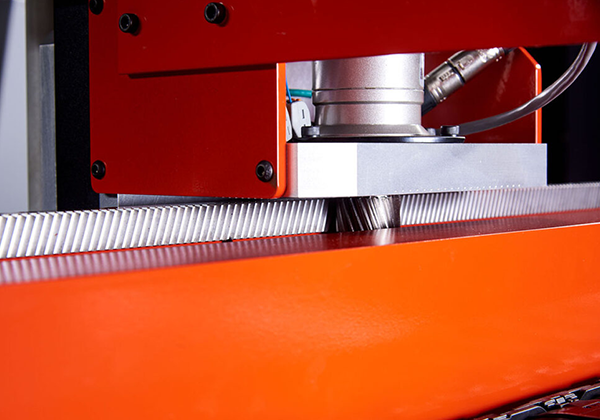

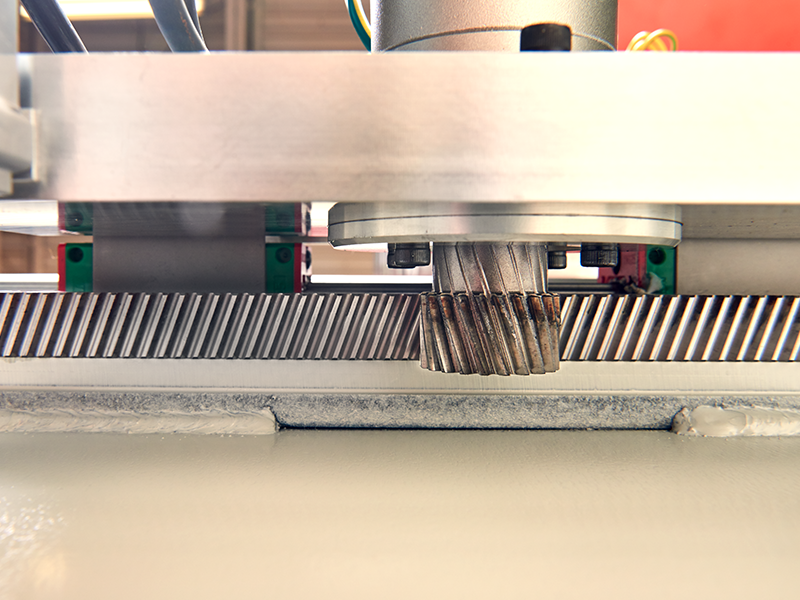

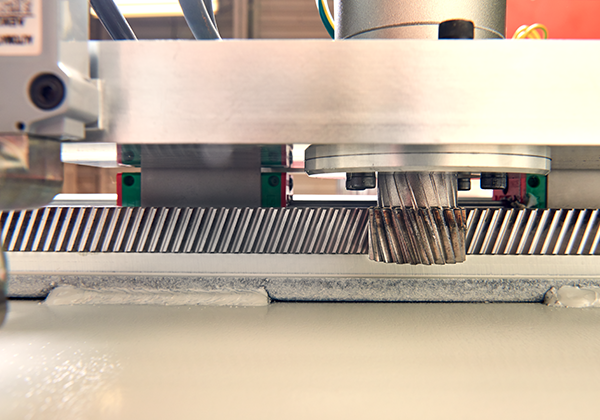

Helical Rack and Pinion Drives

The features X-axis and Y-axis helical rack and pinion drives. This configuration offers enhanced precision, increased load capacity, and more.

Replaceable Slat Table System

With a removable/replaceable slat table design, you can easily customize the table surface based on the material being cut, and replace worn-out slats when needed.

Laser Pointer

The laser pointer makes plate alignment and location finding easy. With this technology, you can streamline the cutting process, improve productivity, and reduce the risk for errors.

Magnetic Breakaway Head

The magnetic breakaway head protects plasma torch and machine from damage in case of collision or unintended contact with the workpiece.

Automatic Torch Height Control

Our advanced torch height control (THC) lifter helps maintain a consistent and optimal distance between the torch and workpiece. This gives precise cuts while protecting the torch and extending consumable life.

Plug-and-Play Installation

Hook the unit up to a power supply and it’s ready to cut. No complex installation required.

Tucked Dual Rails

Precision linear rails are mounted on the machined surface and integrated with helical rack and pinion and precision bearings.

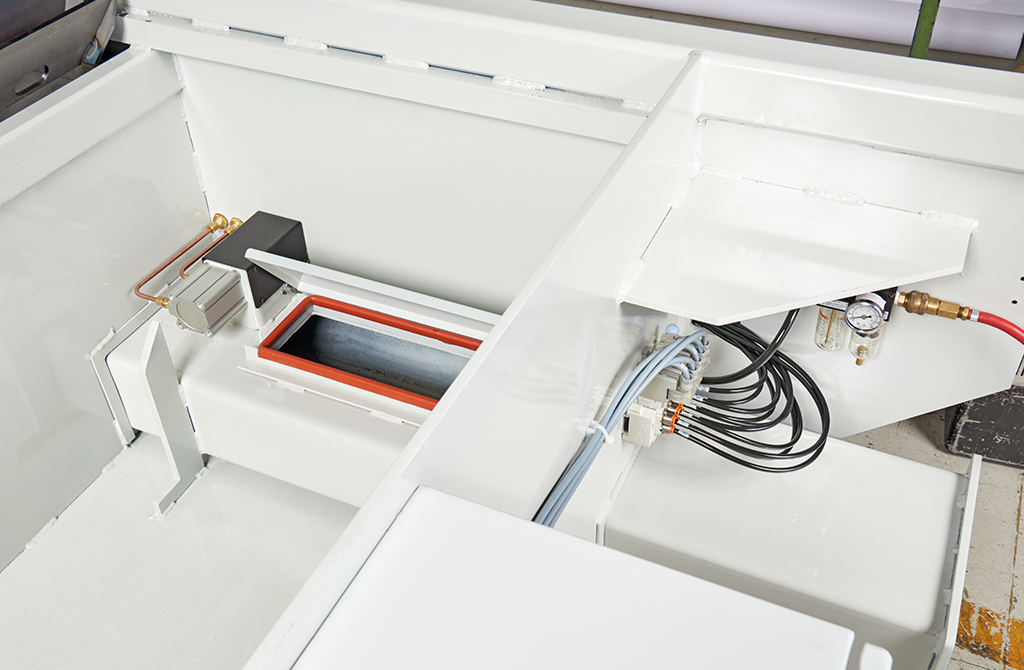

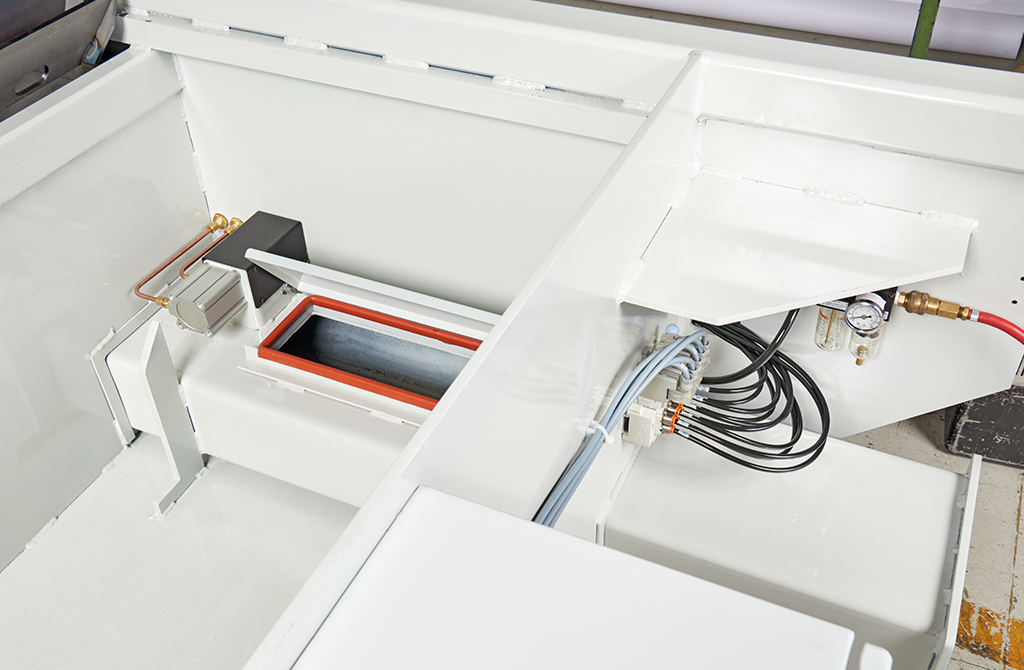

Five-Zoned Air Downdraft Table

Each zone limits the total area to evacuate, reducing dust collector size while optimizing dust collector performance.

Advanced Helical Rack and Pinion Drive Systems

Features 12-foot X-axis dual synchronized drives with helical rack and pinion. It also has a 6-foot Y-axis bridge single drive with helical rack and pinion. This configuration allows for precise motion control, increased stability, and high-speed cutting.

Standard Water Table

Standard Multi-Zoned Downdraft Table

The multi-zone downdraft system minimizes vented area, which increases airflow rate and reduces dust collector size.

Direct Pinion Loading

With direct pinion loading, you can minimize backlash and reduce the potential for positioning errors. This is crucial for maintaining high precision in plasma cutting operations, where even small deviations can lead to significant inaccuracies in the final cut

Power and Gas Options

Table Options

Multiple Sizes

With multiple table sizes available, you can customize the PLASMATIC Pro to meet your needs. It comes in 5’x10’ and 6’x12’ options.

Accessories

Air Scribe Marking System

With our air scribe marking system, you can create clear and precise marks, which promotes cleaner cuts and reduced downtime.

Roller Ball Lifter Unit

Are you cutting thin gauge material? Then you need the roller ball lifter unit. This technology holds down the material and promotes more accurate cuts.

Software and Technology

The PLASMATIC Pro runs on the Hypertherm Phoenix Operating System. It provides consistent product performance with easy-to-use software that empowers the operator to make the optimal cut, every time. The PLASMATIC Pro also features Hypertherm SureCut Technology to further provide excellence in plasma cutting operations

Hypertherm SureCut Technology

AKS Cutting Systems is the only company that provides the full suite of Hypertherm SureCut technology options. SureCut maximizes performance by providing embedded expertise from a combination of tools. These tools include state-of-the-art plasma power supplies, along with CNC and CAM software.

SureCut automatically applies optimized cutting parameters, which simplifies cutting and reduces operator intervention. With the ability to work across multiple cutting technologies, SureCut improves job efficiency. You also get access to remote help if you need to troubleshoot, which reduces downtime in your operation. The SureCut suite of tools includes:

True Hole

True Hole for mild steel produces significantly better hole quality than traditional plasma technology.

True Bevel

Factory tested and easily implemented, True Bevel takes the guesswork out of the plasma bevel cutting process.

Rapid Part

Rapid Part controls and optimizes every step in the plasma cutting process, which reduces cut-to-cut cycle time.

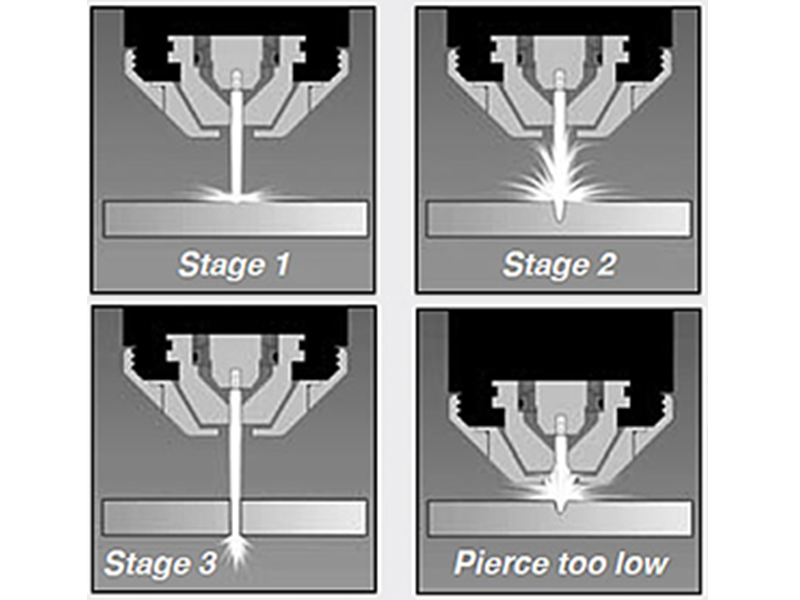

Sensor THC

Sensor Torch Height Control is a CNC-integrated system that provides optimized plasma cut performance and reliability.

ProNest 2025

ProNest CAD/CAM part nesting software helps you achieve greater automation, efficiency, and profitability.

Resources

Support

On-site Installation and Training

The PLASMATIC Pro features four to five days of onsite installation and training by a certified AKS technician.

Two-Year New Machine Warranty

The AKS new machine warranty covers parts and labor. See terms for more information.

Easy Access to New Consumables

Participation in our Elite Edge Customer Success Program offers cost savings on Hypertherm consumables and AKS service.

Lifetime Phone Support for Easy Troubleshooting

Our team covers all your service and cutting support needs. Must purchase Hypertherm consumables from AKS Cutting Systems to be eligible.