Premium Precision Waterjet Cutting Machine

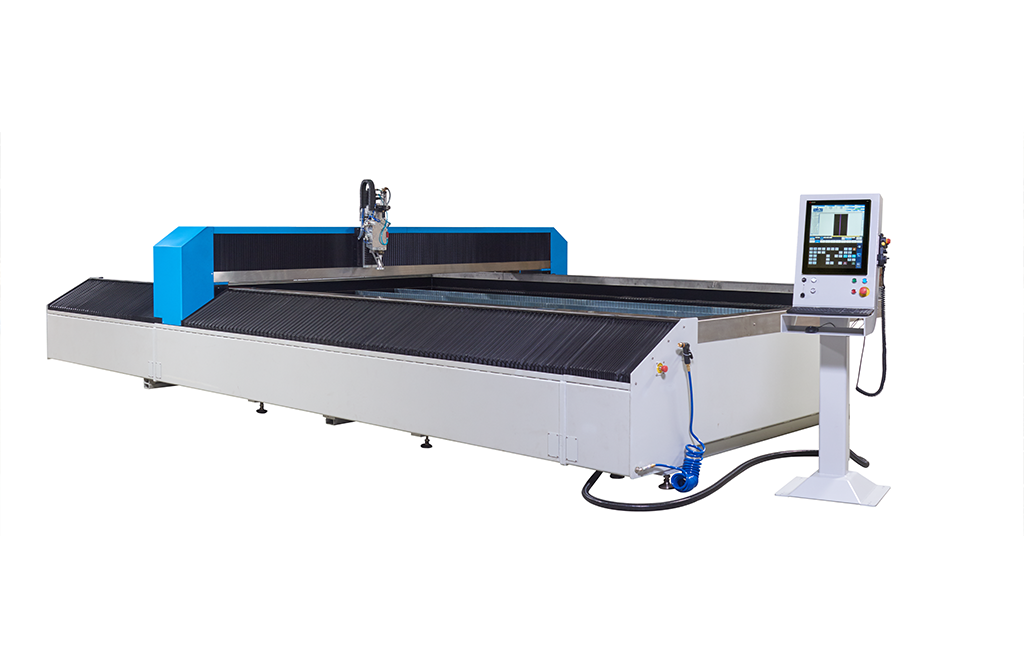

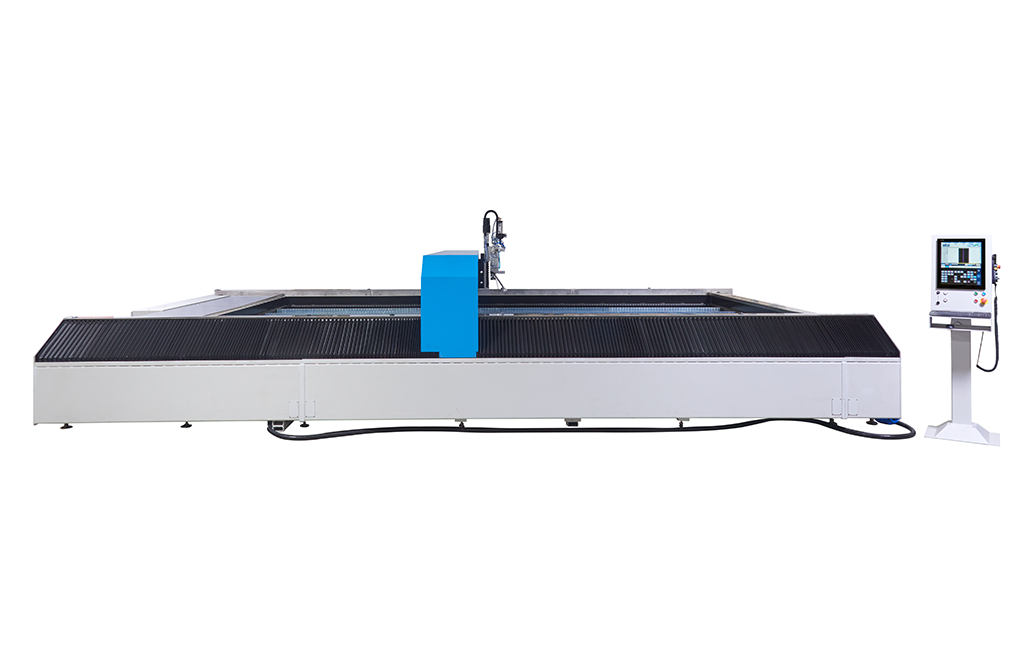

Seeking a precision waterjet that delivers high accuracy and high performance even in the most demanding applications? Consider the water-kut x4, a gantry machine with a specialized ball-screw design that empowers your operations with extreme functionality.

The water-kut x4 is an extremely customizable solution that enables you to tailor your machine to your precise needs. We offer a variety of tools, features, and options that our team will guide you through to match you with the perfect solution. Ready to get started? Contact us today.

Specifications

| Motion Accuracy | +/- 0.001-inch per 3-feet accuracy of motio |

| Travel Speed | 800 ipm travel speed |

| Screen Size | 19-inch screen |

| Max Cut Width | Up to 12 feet |

| Max Cut Length | Up to 20 feet |

Features

Plug-and-Play Installation

Hook the unit up to a power supply and it’s ready to cut. No complex installation required.

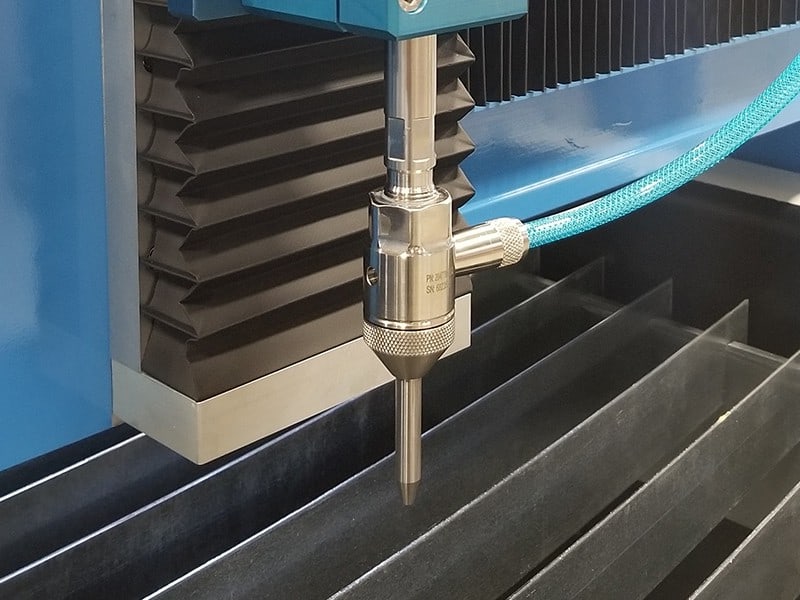

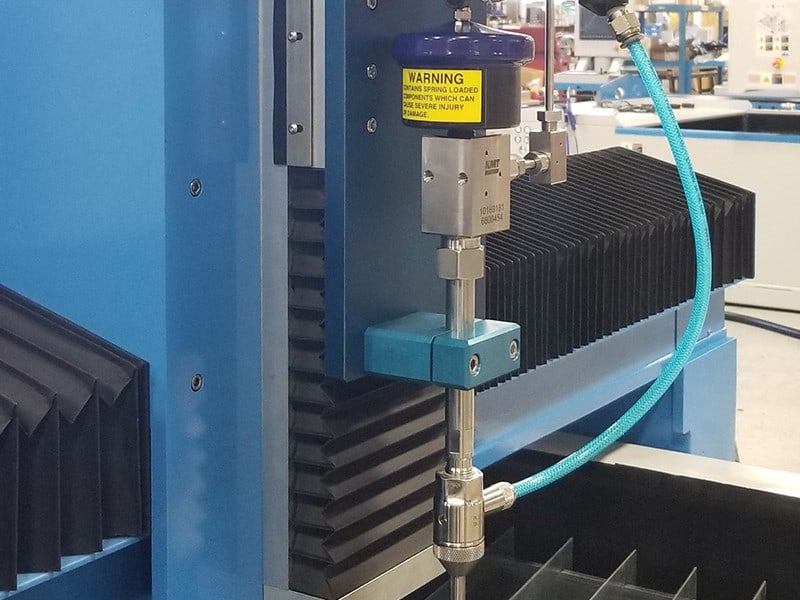

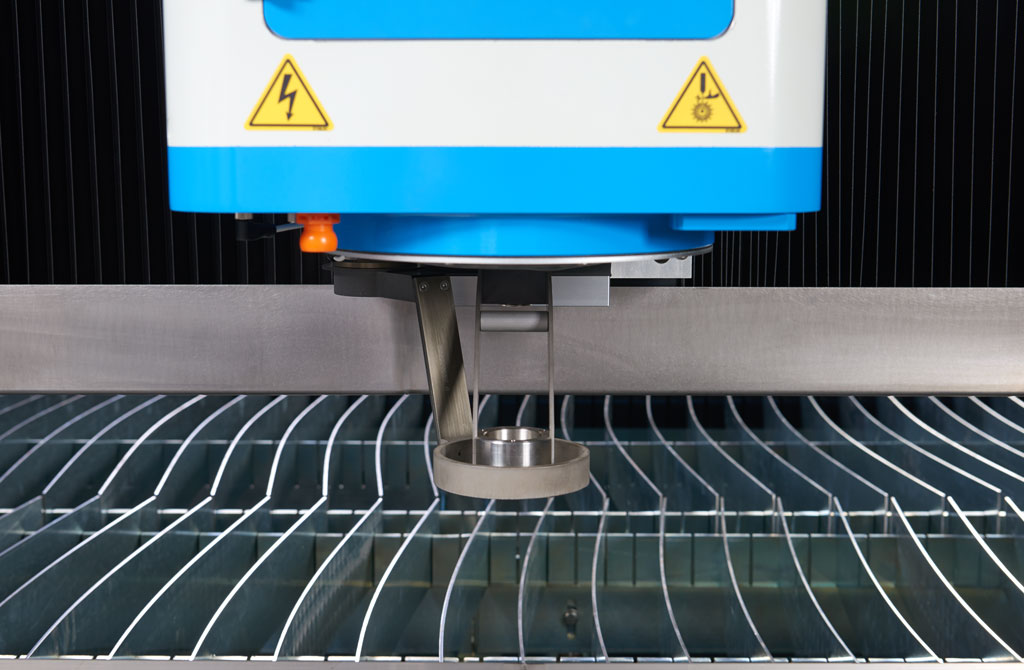

KMT High-Pressure Cutting Head

We partner with KMT to bring you the fastest, most efficient and accurate cutting heads on the market. This helps ensure quality cuts, every time.

670-Pound Abrasive Bulk Feeder Hopper

Extend cutting times and increase efficiency with this large hopper capacity. The 670-pound hopper allows the cutting process to continue for extended periods without frequent refilling.

Adjustable Abrasive Mini-Hopper

An adjustable abrasive mini-hopper is a cost-effective way to optimize abrasive flow and enhance cutting quality. It easily collects the abrasive, making it simple to recycle and reuse the material within the waterjet cutting system.

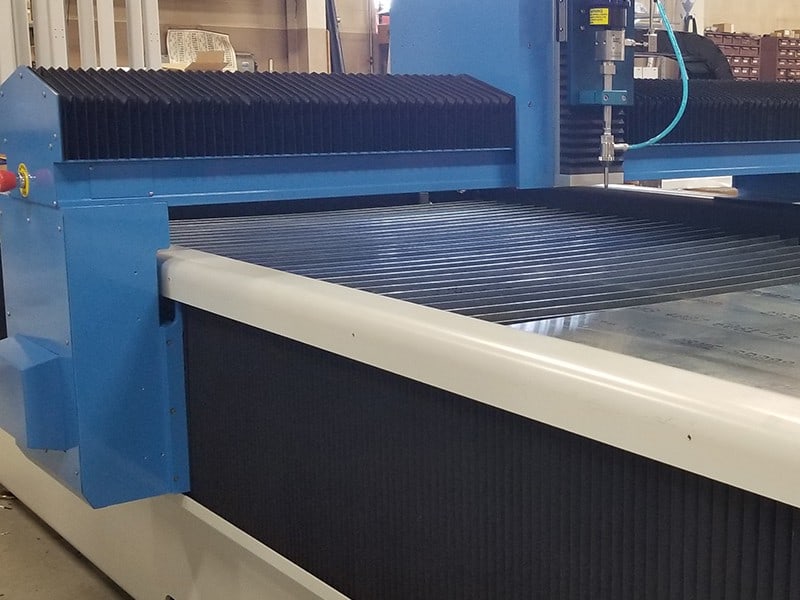

Removable/Replaceable Slat Table System

With a removable/replaceable slat table design, you can easily customize the table surface based on the material being cut, and replace worn-out slats when needed.

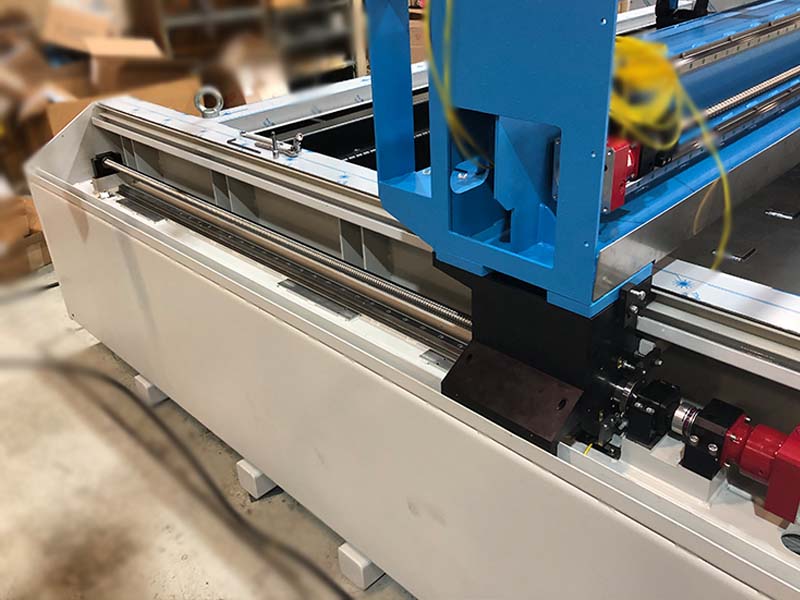

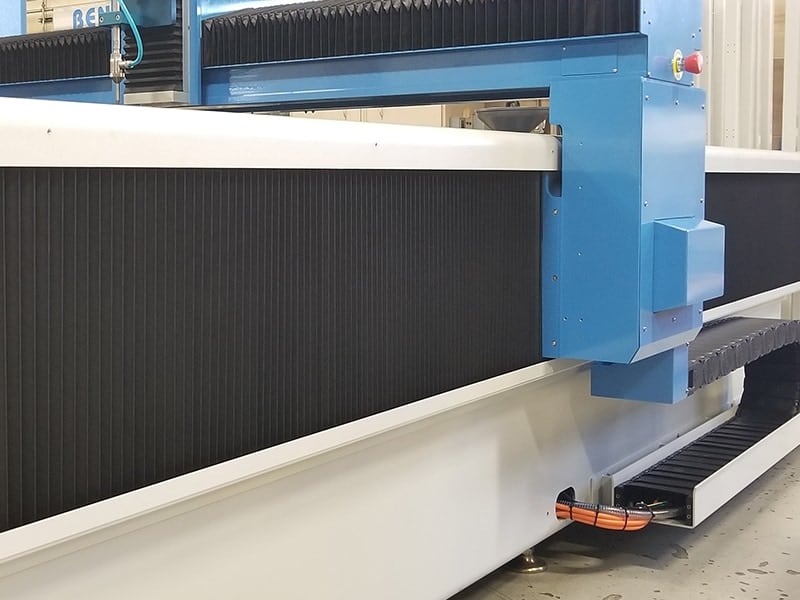

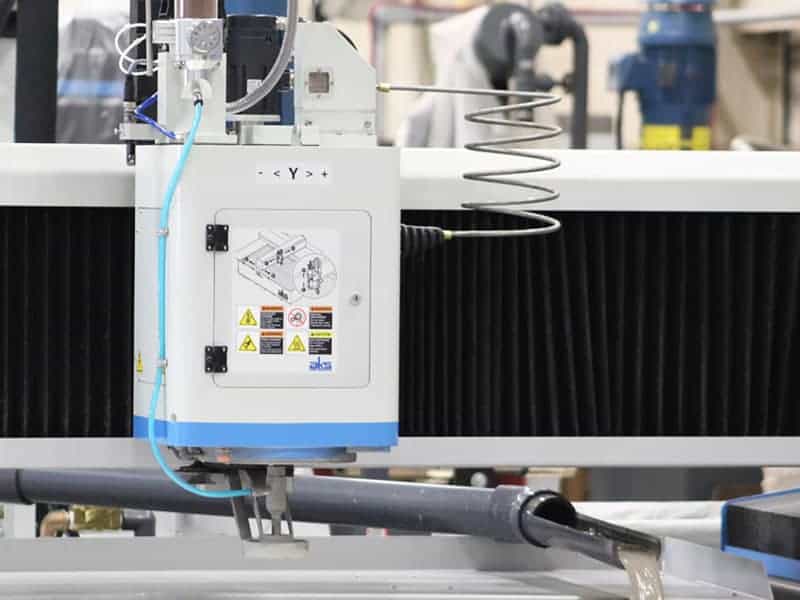

Bellow Cover Assemblies on X and Y Axes

Our bellow cover assemblies protect your machine from contaminants, help minimize downtime, and provide enhanced safety to your operators

X-, Y-, and Z-Axis Ball Screw Drives

Get precise depth control and multi-level cutting with our multi-axis ball screws. This results in better accuracy and high-quality cuts, every time.

Pump Options

| Brand | Series | Pressure | Horse Power | Style |

|---|---|---|---|---|

| KMT | NEO | 60,000 | 30 | Intensifier |

| KMT | NEO | 60,000 | 50 | Intensifier |

| KMT | Pro | 90,000 | 50 | Intensifier |

| KMT | Pro | 90,000 | 60 | Intensifier |

| KMT | Pro | 90,000 | 125 | Intensifier |

| KMT | SL-VI | 60,000 | 50 | Intensifier |

| KMT | SL-VI | 60,000 | 100 | Intensifier |

| KMT | Tri-Line | 55,000 | 30 | Direct Drive |

Table Options

Multiple Table Sizes

With multiple table sizes available, the water-kut x4 offers maximum convenience. The machine comes in the following sizes: 4’x5’, 6’x12’, 12’x20’.

Accessories

Automatic Abrasive Removal System

Efficiently remove and recover abrasive particles using our automotive abrasive removal system. This technology helps improve efficiency, reduce waste, and extend the life of cutting components.

Stand-Alone Chiller

A stand-alone chiller regulates and maintains temperature of the water, ensuring optimal cutting performance and protects the machine from overheating.

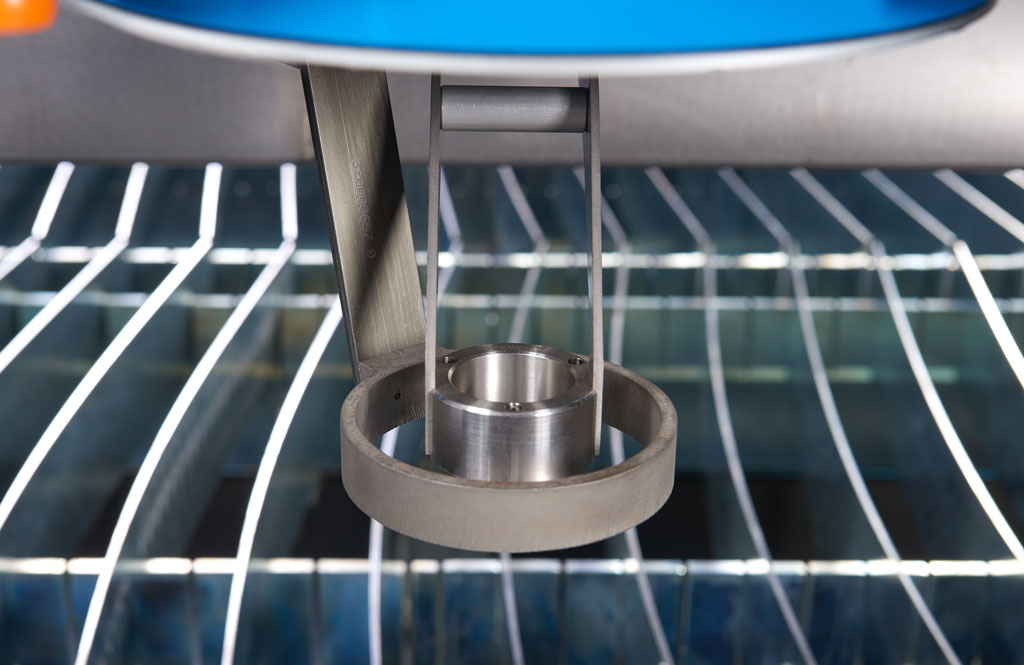

Collision Sensor

The collision sensor ring can detect most crashes of the nozzle, which protects both your equipment and the workpiece. The collision sensor is pneumatically engaged and can be easily reset. (Requires the purchase of an automatic touch probe).

Automatic Touch Probe

Easily maintain optimal distance between the nozzle and cutting material with an automatic touch probe. It can be programmed at certain distance intervals, then adjusted during the cutting process. This allows you to compensate if the workpiece warped or not flat.

Wired Handheld Remote Pendant

This machine-tool quality wire remote pendant allows easy jogging of the head in all three axes via a rotary dial for tactile feedback.

Laser Pointer

Improve plate alignment and enhance cutting accuracy with a laser pointer add-on. This technology helps operators avoid misalignment or improper positioning of the material, reducing the chances of cutting errors.

Closed Loop Water Recycling System (CLS)

Minimize water consumption and waste with our closed-loop water recycling system. You’ll reduce your impact on the environment and save money on water bills and wastewater treatment expenses.

Taper Control System (TCS)

The TCS allows you to achieve high-accuracy parts by angling and rotating the waterjet taper away from the part straight edge. The result is a final part that’s produced faster and with straighter walls, regardless of the thickness or composition of the material being cut.

Software and Technology

Mitsubishi 80W Industrial CNC Controller

Enabled with Mitsubishi CNC technology, the water-kut x4 provides high productivity and easy operability.

Metamation CAM & Auto True Shape Nesting Software

Metamation’s software allows easy CAD import and design, toolpath generation, nesting optimization, and more.

Resources

Support

On-site Installation and Training

The water-kut x4 features 10-day onsite installation and training by a certified AKS technician for your precision waterjet machine.

Two-Year New Machine Warranty

The AKS new machine warranty covers parts and labor for two years. See terms for more information.

Easy Access to New Consumables

Participation in our Elite Edge Program offers cost savings on Hypertherm consumables and AKS service.

Lifetime Phone Support for Easy Troubleshooting

Our customer service team covers all your service and cutting support needs. Must purchase Hypertherm consumables from AKS Cutting Systems to be eligible.