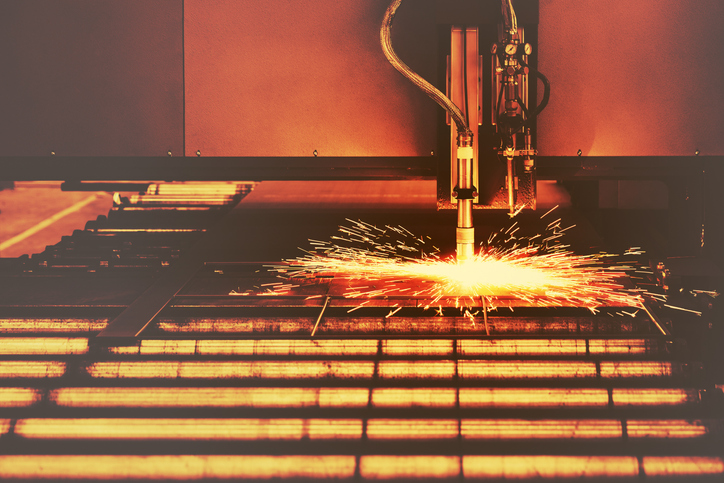

When you must achieve superior plasma cutting results, AKS Cutting Systems equipment paired with Hypertherm technology is unbeatable. Together, they provide a cutting solution that enhances productivity, improves cut quality, and ensures reliability in every project. Below, we’re exploring how this partnership can transform your plasma-cutting operations and elevate your business.

Unmatched Precision

AKS plasma cutters utilize Hypertherm technology to achieve the highest accuracy in every cut. In many cases, our customers achieve laser-like quality at a fraction of the cost. In fact, Jorgensen Steel replaced its laser machinery with three AKS plasma cutting machines. The company noticed an issue with the quality of laser-cut components, especially on materials exceeding ¼-inch thickness. The switch to plasma addressed the concerns regarding the quality of the cuts, all at a lower price point. This precision allowed the company to operate with increased efficiency, resulting in reduced production costs.

Customization for Your Needs

Perhaps one of the biggest advantages of using AKS technology is its ability to be customized to your exact needs. Whether you need a cost-effective solution like the Plasmatic or a heavy-duty industrial cutter like the dura-kut, we have the perfect solution for you. And we make it easy to know what’s going to be the best option for your business. When you look at any of our plasma-cutting machines, you’ll see a section entitled “Power and Gas Options.” Simply choose a power supply, then a gas console, and we’ll instantly tell you what you can cut with that combination.

Additionally, we have add-ons that maximize your productivity. You can customize your machine with a variety of equipment, like the robo-kut, tube-kut, or self-cleaning machinery. These add-ons help you improve efficiency and maximize profits. In fact, we were able to help WesLor customize its dura-kut to enhance operations. With the addition of our robo-kut, the company was able to deliver expedited plasma bevel and cutting operations.

Versatility

The combination of AKS and Hypertherm technologies allows for versatile cutting capabilities. From thin sheets to thick plates, and even beveling operations, these systems can handle it with ease.

Support and Expertise

When you order an AKS machine powered by Hypertherm consumables, our support goes far beyond the sale. You get access to a wealth of knowledge and support, ensuring you receive the guidance and assistance needed to maximize your cutting system’s potential.

We’re there to help each of our clients when they need it. Customers like Cleveland Tank and Supply are always appreciative of experienced service managers like Scott Krankowski, who can help get them back up and running quickly. Ben Crandall, plant manager at Cleveland Tank and Supply, had this to say about Scott’s support:

“I just wanted to put in a good word for Scott Krankowski from AKS Cutting Systems in Cleveland,” he said. “Scott has helped us out with our AKS plasma tables and the Hypertherm products they use for the past 10+ years. His customer service and knowledge of the product is some of the best I’ve experienced in my manufacturing career. He’s helped me fix major issues over the phone because he knows the systems so well. It’s reasons like this that keep us using Hypertherm/AKS products.”

AKS Cutting Systems Helps You CutEVERYDay with a High-Quality Plasma Cutting Machine

At AKS Cutting Systems, we’re dedicated to helping our customers maintain efficient cutting operations. With our plasma-cutting machine solutions and exceptional customer service, we help our customers experience better uptime than the competition. When you need a partner who can provide a high-quality plasma-cutting machine, turn to us. With our expert service team and innovative technology, we’re here to support you every step of the way. Contact us to get started.