When operating a CNC plasma cutting system, it’s imperative to use consistent gas pressure to ensure the highest quality cuts. Additionally, ensuring a steady plasma cutting gas pressure may help extend the life of your torch. But, how do you guarantee a steady gas pressure while the machine is in use? Here, we break down everything you need to know.

What is CNC Plasma Cutting?

Plasma cutting uses a high velocity stream of ionized gas to cut through electrically conductive metals. These metals may include steel, stainless steel, aluminum, brass, and copper. During the cutting process, an electric arc is struck between an electrode and the workpiece. The electrode is recessed in a water- or air-cooled gas nozzle that constricts the arc, which causes the plasma jet to form. When the plasma jet hits the material, it melts the metal and the gas flow removes it from the cut.

CNC plasma cutting machines are computer controlled, allowing them to deliver precise and accurate cuts, every time. These high-tech, reliable systems are perfect for a wide range of industries, including the fabrication and welding, automotive, and construction sectors, among others.

Why is a Consistent Plasma Cutting Gas Pressure Important?

Plasma cutting gas flow plays a vital role in achieving quality cuts. If the gas pressure is too low, the plasma stream will be unstable and will not be able to effectively cut through the material. On the other hand, if the gas pressure is too high, the plasma stream will be too powerful and can cause the material to become distorted or blown apart.

Using consistent gas pressure helps to maintain a stable plasma stream, which results in more precise cuts. If the gas pressure is not consistent, it can lead to variations in the quality of the cuts, which can result in rework or even scrap material. A consistent gas pressure also helps extend the life of the plasma torch, as fluctuations can put unnecessary strain on the equipment.

How Can You Ensure a Consistent Plasma Cutting Gas Pressure?

Using a quality CNC plasma cutting machine is the best way to ensure consistent gas pressure. For example, all AKS Cutting Systems machines have a dynamic gas control system that governs the incoming gas pressure to the proper flow rates. This helps ensure a high-quality cut, every time.

About AKS Cutting Systems Equipment

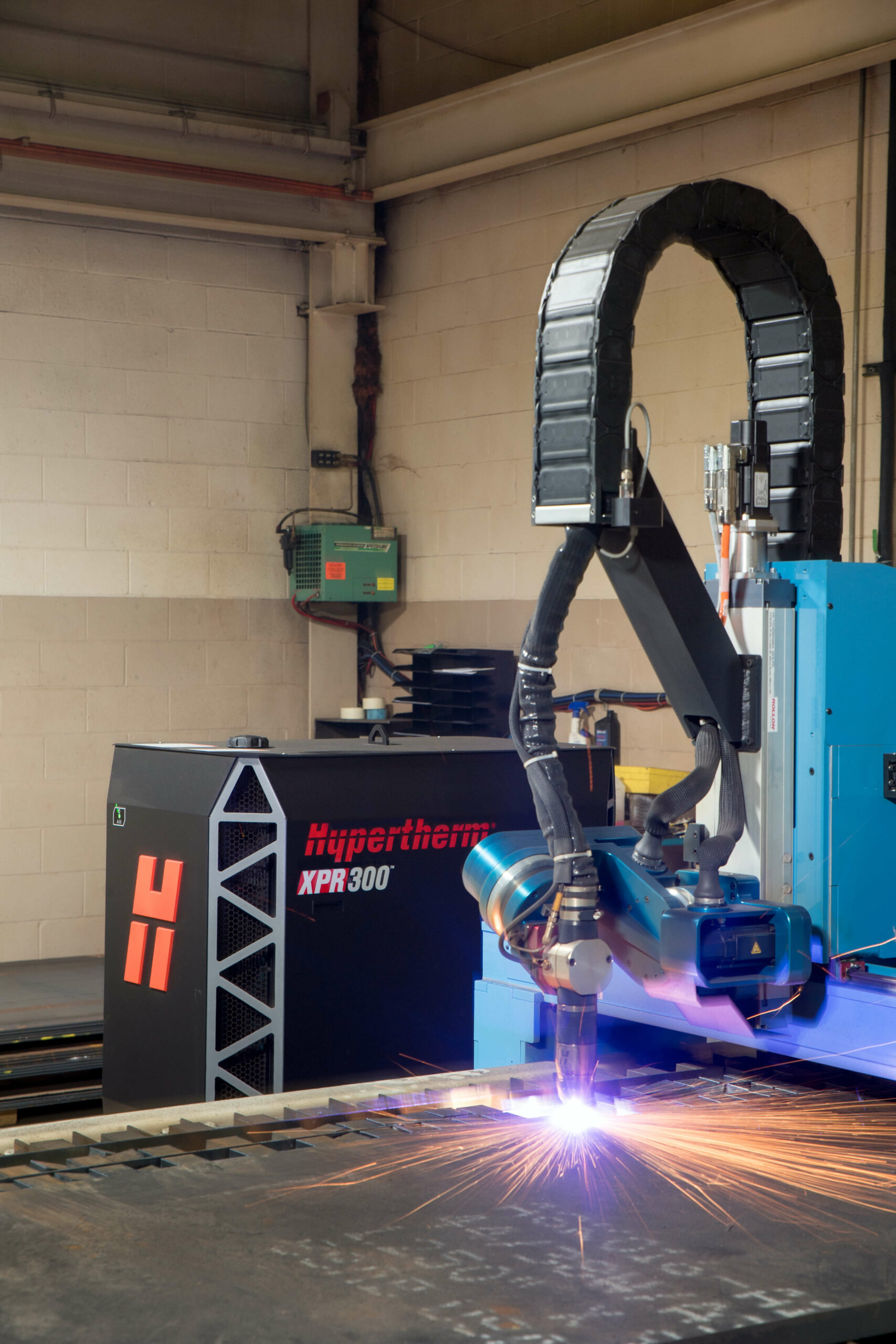

Our CNC plasma cutting machines — including the tru-kut, accu-kut, and dura-kut models — are the industry standard for high-quality plasma cutting. With over 100 years of experience and a robust relationship with Hypertherm, we’re ready to match you with the best plasma cutting system for your organization.

Since 1912, AKS Cutting Systems and our parent company, Kiffer Industries, have been providing the best machines from our factory headquarters in Cleveland, Ohio. We are a fourth-generation, family-owned and operated company that provides Made-in-the-USA equipment for a variety of industries. Our CNC plasma, waterjet, oxy-fuel and fiber laser cutting systems regularly serve businesses in the plate metal, tube and pipe, sheet metal, and fabricating sectors.

We have a strong reputation for durability, accuracy, and reliability, with thousands of happy customers worldwide. We also offer our customers access to an extensive service and support network, should any issues arise.

Work with AKS Cutting Systems for Your Plasma Cutting Needs

When you’re ready to upgrade to a CNC plasma cutting system, we’re here to help. Contact our helpful team today.