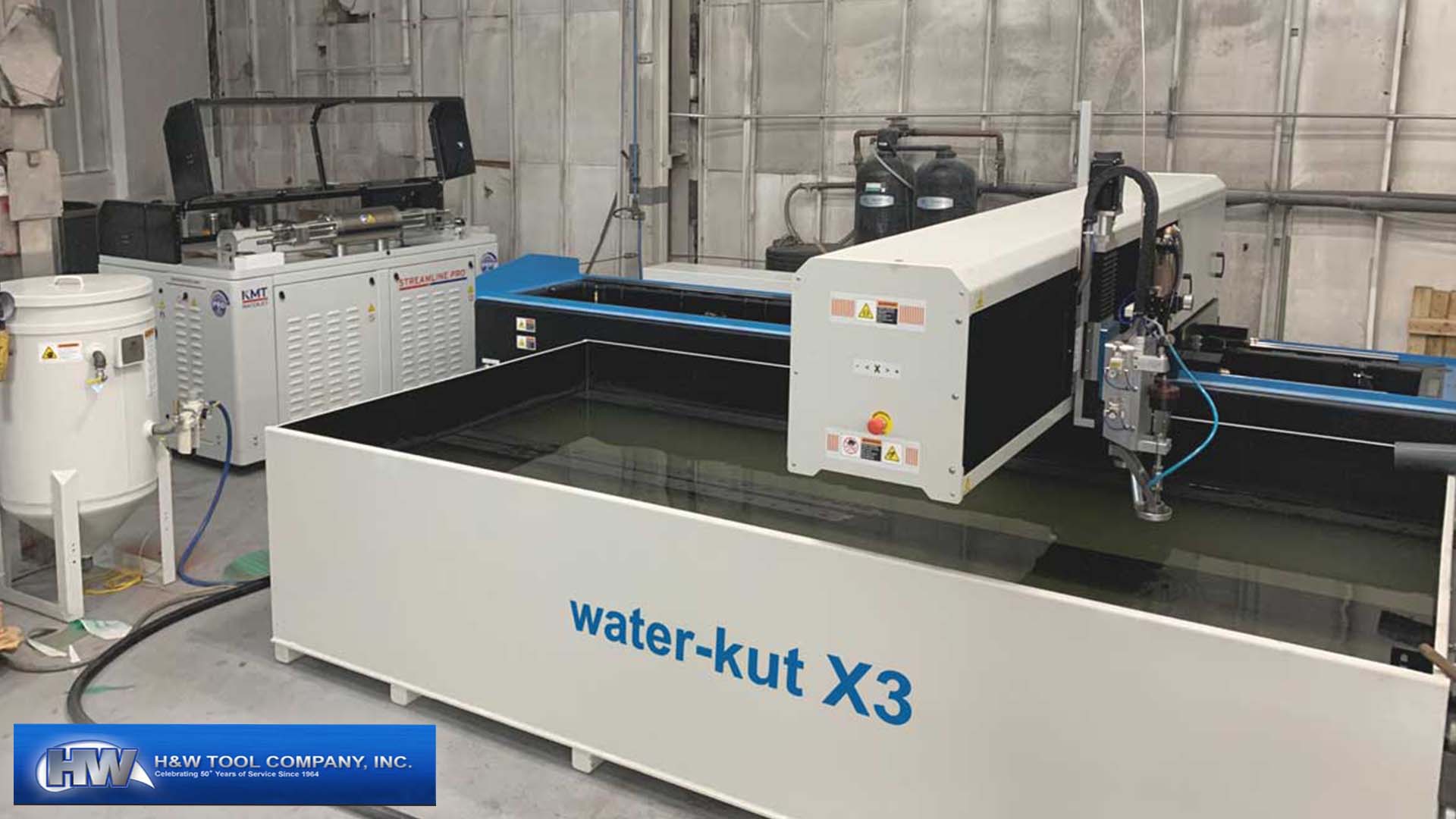

H&W Tool Co., a family-owned tool and die company that provides services to the aerospace and medical communities.

When they needed new waterjet cutting tables at its plants in Ohio, New Jersey and Virginia they turned to AKS Cutting Systems.

Since installing their first AKS water-kut a few years ago to installing their latest AKS water-kut unit in February 2021, the company has seen improved performance, higher efficiency and significant time and cost savings.

“We had WARDJet systems before and the reason we got away from that is because we were actually doing more repairs than we were making on a part,” says Christopher Klesta, H&W Tool shop manager of the company’s Euclid, Ohio, location. “For example, we did about $98,000 in waterjet work last year, and I paid about $102,000 in repairs.”

Earlier this year, 12 weeks after purchasing a machine for the Euclid plant, AKS delivered and installed it according to H&W Tool’s unique specifications, which included a different layout to fit the facility. Klesta worked closely with AKS engineers throughout the whole process. After four days, training was underway and small programming had begun. The following Monday, the machine was fully running, producing products for customers.

“It’s very user-friendly. After just one day of training, I was already cutting our standard parts, which is very unusual for a brand-new machine” Klesta says. “We had to rewrite our programming, which is not uncommon when going from one type of machine to the next, but with the help of AKS engineers, we were able to streamline that process a lot faster.”

AKS also was able to modify the rise and fall of the water table to meet H&W Tool’s specific need for a greater depth of water.

“We wanted eight inches of raise and lower water level, and AKS was able to accommodate us on all of our machines so far,” Klesta says.

Features and Results

Klesta estimates a labor savings of 40 to 50 percent due to less downtime and faster cutting.

“The performance of the machine is outstanding. It outruns and out-cuts any other waterjet machine that I’ve ever worked on,” says the 30-year waterjet industry veteran.

The completely sealed head offers a big advantage, eliminating clogged nozzles caused by spray back, which is common in the type of cutting H&W Tool performs.

The unit’s 90K PSI intensifier pump creates a streamlined waterjet stream, allowing operators to cut without a rooster tail, which would dig into the parts at the bottom side of the surface.

“Since we cut such thick parts, up to almost 3.5 inches thick, if we didn’t have the high pressure and the accuracy of the AKS unit, we would have wash out — either scrapping the part or we would have to keep so much stock that when it comes back at a later process, it would cause us more time on our other machines to finish the product,” Klesta says. “This would mean lower productivity, less commits to the customer, and delays for customers.”

AKS water-kut machines feature an AKS automatic garnet removal system, which Klesta says is the best available due to the fact that it pushes air through nozzles at the bottom of a tank. “Most machines don’t have a push out system, just a suck-in system where it just draws whatever’s close. The AKS system actually swirls and agitates the tank, so it’s constantly moving the wasted material out, instead of collecting.”

So far, H&W Tool’s water-kut machine in Euclid has roughly 750 hours on it, without the need for any maintenance.

“For anyone who’s looking for a waterjet style machine, AKS would definitely be my first choice, hands down,” Klesta says.