What if there were a way to make your plasma cutting processes faster? What if you could process more material per hour, allowing you to better supply downstream operations? With Hypertherm’s HySpeed technology, you can. This optimization allows you to cut thin-gauge materials at more than double the speed of standard plasma cutting. Below, we’re exploring this technology — and how it partners with a top-rated plasma cutter — to deliver faster results.

What is HySpeed?

As mentioned above, HySpeed is a process optimization that changes how the plasma torch moves during the cutting phase. Traditionally, the torch approaches the material, performs the cut, retracts, moves to the next pierce point, then approaches again. Those repeated motions add up to a significant amount of lost time.

HySpeed changes that. After its initial approach, the torch remains at the proper height and moves directly from one pierce point to the next without retracting. This streamlines the process and speeds up manufacturing.

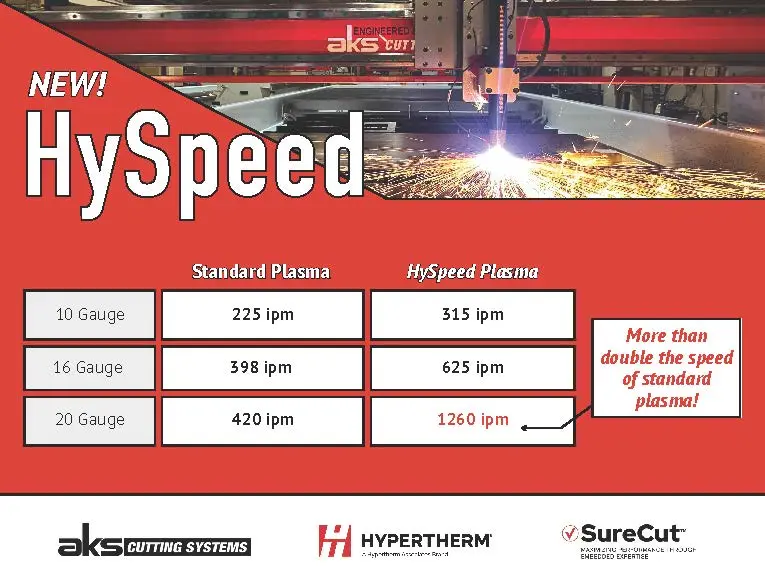

The Speed Difference

The difference HySpeed makes is clear. Compared to standard plasma cutting, HySpeed offers dramatic increases in inches per minute (ipm).

- 10-gauge mild steel: 225 ipm → 315 ipm

- 16-gauge mild steel: 398 ipm → 625 ipm

- 20-gauge mild steel: 420 ipm → 1260 ipm

For shops that regularly process thin materials, HySpeed can mean completing the same work in half the time. And since you’re cutting faster, your downstream operations (forming, welding, assembly, etc.) stay better supplied and on schedule.

Balancing Speed and Quality

Any time you increase cutting speed, there’s a concern about maintaining cut quality. HySpeed will slightly reduce the edge quality. However, the loss is minimal. The tradeoff is more than acceptable when weighed against the massive productivity gains. When your system can process more sheets per hour, your shop gains capacity without needing additional machines, operators, or floor space.

Ideal for HVAC and Mechanical Contractors

Hyspeed was designed with thin-gauge material applications in mind. This is exactly the kind of work HVAC and mechanical contractors handle every day. With the HySpeed process optimization, these businesses can benefit from advancements that improve their bottom line.

How to Incorporate HySpeed into Your Operations

HySpeed requires a top-rated plasma cutter that’s physically capable of the acceleration, deceleration, and motion control it requires. AKS Cutting Systems’ PLASMATIC Pro, accu-kut, and tru-kut are all engineered to stand up to HySpeed’s demands. That’s because they contain features like helical rack and pinion drives and AC brushless servo motors. This well-designed, stable motion control package ensures accurate results. Additionally, their rigid heavy-duty frames provide the reliability necessary for success.

Contact AKS to Get Started with HySpeed

If you’re ready to upgrade to HySpeed, reach out to the team at AKS Cutting Systems. We’ll work with you to understand your needs and recommend the best solution for your business. Our top-rated plasma cutting systems are renowned for their ability to handle tough jobs and improve productivity.

Since 1912, AKS Cutting Systems and our parent company, Kiffer Industries, has been on the forefront of machine tool design and build from our factory headquarters in Cleveland, Ohio. As a fourth-generation, family-owned and operated company, AKS Cutting Systems is one of the few Made-in-the-USA manufacturers of CNC plasma and waterjet cutting machines. If you’re ready to see what we can do for you, reach out today.