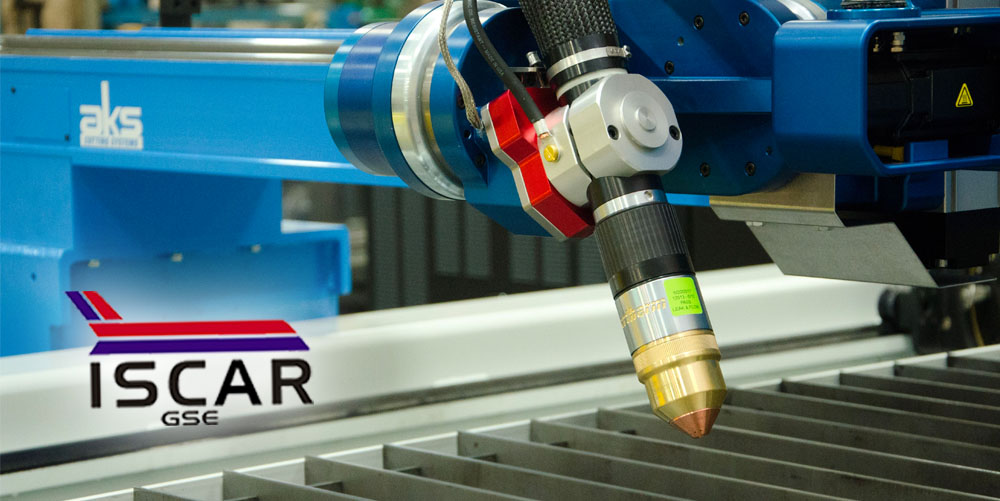

When Iscar GSE, a Miami-based company that builds state-of-the-art ground service equipment for the aviation industry, wanted to increase the precision of its operations, the solution was a plasma cutting machine from AKS Cutting Systems.

While connecting at a trade show, followed by an on-site visit, representatives from the companies discussed Iscar GSE’s needs in efficiently producing airport equipment like baggage carts, container dollies, lavatory service pallets and more.

What began as a discussion about straight plasma cutting and tube cutting eventually evolved to include the process of robocutting, as well. Iscar GSE’s manager and director, Israel Carruyo, visited the AKS facility in Cleveland to fine-tune the details.

In 2015, the company purchased AKS’ accu-kut system, which offers the highest accuracy, rigidity and stability available; has multiple plasma heads or oxy-fuel torches; and offers optional robo-kut and tube-kut capabilities. According to Carruyo, the machine has increased efficiency and precision dramatically, as well as enabling Iscar GSE to incorporate robotics into its production process.

“The precision that we got out of the machine was a prime point for our operation,” he said. “We were able to get into robotics, which was something that we could not do with our previous machine because it was very limited in size and cutting capabilities. (The accu-kut) gave us the precision so that we could cut parts and be able to put them in a robot and fabricate other pieces of other equipment that we manufacture — so we could do them faster and with better precision and quality.”

Iscar GSE performs sheet cutting, including thicknesses of up to 1.5 inches, as well as scribing to carve customer names in metal parts, making equipment easier to find and reducing theft in the busy airport setting.

“The machine has been a great addition to our operations because of its features and all the things that we’ve been able to do with it,” Carruyo said. “We also cut materials for other companies occasionally, and they’re very happy with the precision and the cuts that the machine is able to do. The quality of the cuts expedites and minimizes our work, too.”

Customer Service Experience

Another benefit of working with AKS has been the customer service, he added. This includes getting parts, receiving advice on machine operation, and even troubleshooting issues over the phone.

“If you have to wait for somebody to come and fix your machine, it definitely adds time to your production,” Carruyo said. “So by us being able to do that through the tech support people, we’ve learned a lot about the machine.”

Carruyo has been so impressed with the machine that Iscar GSE now serves as a demo site for other potential AKS clients who want to see the accu-kut in action.

“I wouldn’t buy any other machine than the AKS — and if I ever consider changing it or upgrading to a bigger machine, I’ll go straight to AKS,” he said. “If anyone wants to see the machine, they come and see it. My advice is that if they need a machine, this is the one they need to buy.”