Plasma or oxy-fuel cutting: which is best for your job shop?

Plasma or oxy-fuel cutting: which is best for your job shop? It all depends on several factors, including the type of metal you need to cut, thickness of material, and cost. For thicker metals, an oxy-fuel is typically the better way to go, while precision cutting of stainless and aluminum makes plasma the ideal tool. Understanding the key differences between the two cutting technologies is crucial in knowing which to use. Here’s a quick primer.

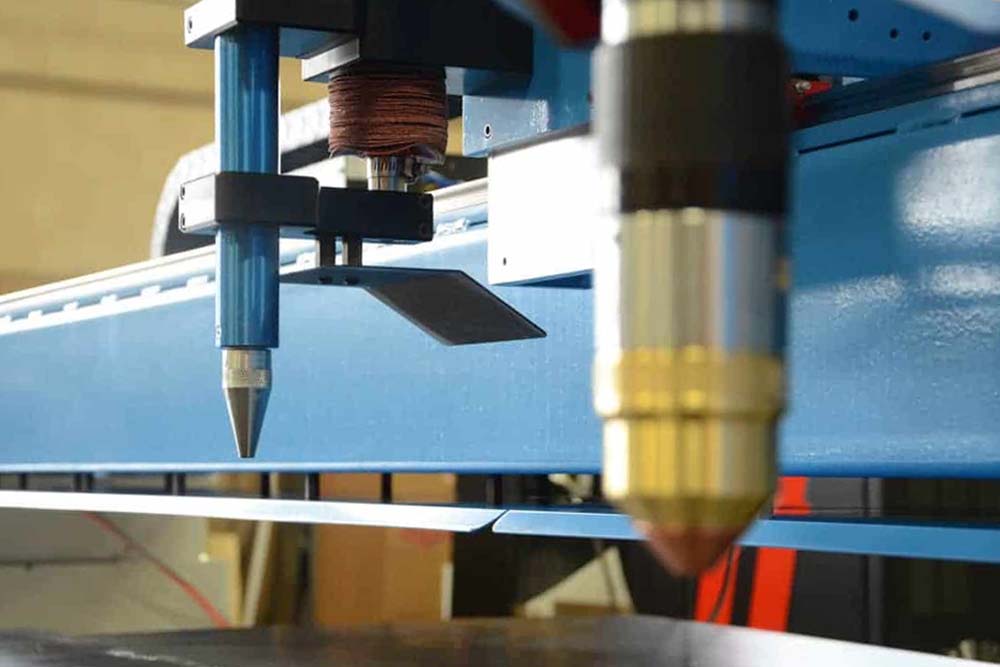

Plasma Cutting

Plasma cutting uses an electrical channel of superheated, electrically ionized gas, or plasma, which melts the material to cut it. Ideal applications for plasma cutting include steel, brass, copper and other conductive metals.

Plasma cutters are frequently used by fabrication shops, automotive repair and restoration, industrial construction, and salvage and scrapping operations. With its high speed, precision cuts and low cost, plasma cutting is suited to industrial CNC applications.

Key benefits of plasma cutting include:

- The ability to cut a variety of very thin, electrically conductive metals, including a wide range of steel, stainless steel, aluminum, copper and more up to 2 inches thick

- Greater cutting versatility, including stack cutting, beveling, shape cutting, gouging and piercing of metals

- Precise cuts at faster speeds — plasma can cut thinner metals faster than oxy-fuel, with minimal material distortion

- Plasma cuts with minimal slag for a smoother cut than oxy-fuel

- Greater ability to cut shaped metals, such as domes or tubes

- Lower cost with no preheating required, and greater ease of use

Oxy-fuel Cutting

Oxyfuel cutting is a thermal cutting process that uses oxygen and fuel gas, such as acetylene, propane, propylene or natural gas, resulting in an intensified chemical reaction within the steel oxidation process that acts rapidly and results in a “cut edge” to cut through materials. The oxygen/fuel gas flame preheats the steel to its ignition temperature, which is then directed at the metal to create a chemical reaction between the oxygen and the metal to form iron oxide, also known as slag. The high-power oxygen jet then removes the slag from the kerf. Cut quality, preheating times and thicknesses can be influenced by the type of fuel gas used.

Advantages of oxy-fuel cutting include:

- Excellence in cutting thick metals, such as cutting carbon steel 2 inches to 6 inches thick at high cut speeds

- The ability to equip your machine with multiple oxy-fuel torches to increase productivity and minimize processing time

- Smooth, vertical planes of cut that create metallurgically perfect oxidized surfaces

- Carbonizing and hardening within the heat-affected zone

How to Decide?

While each cutting technology has its advantages, the most important factors to consider when choosing between plasma and oxy-fuel are the types of metal your shop cuts most often and the material thicknesses.

If you find that you’re consistently cutting thicker metals, an oxy-fuel system likely makes the most sense for your operations, giving you time and cost savings. However, if you require precision cutting of stainless and aluminum, the plasma cutter is your best choice.

While both plasma and oxy-fuel have a place in most metal-processing applications, your operations could benefit from having both systems in place. To help determine the best technology for your individual requirements, talk to an AKS rep today.