What’s your shop’s most challenging plasma cutting application? If you said cutting domes, you’re not alone.

By Chris Phillip

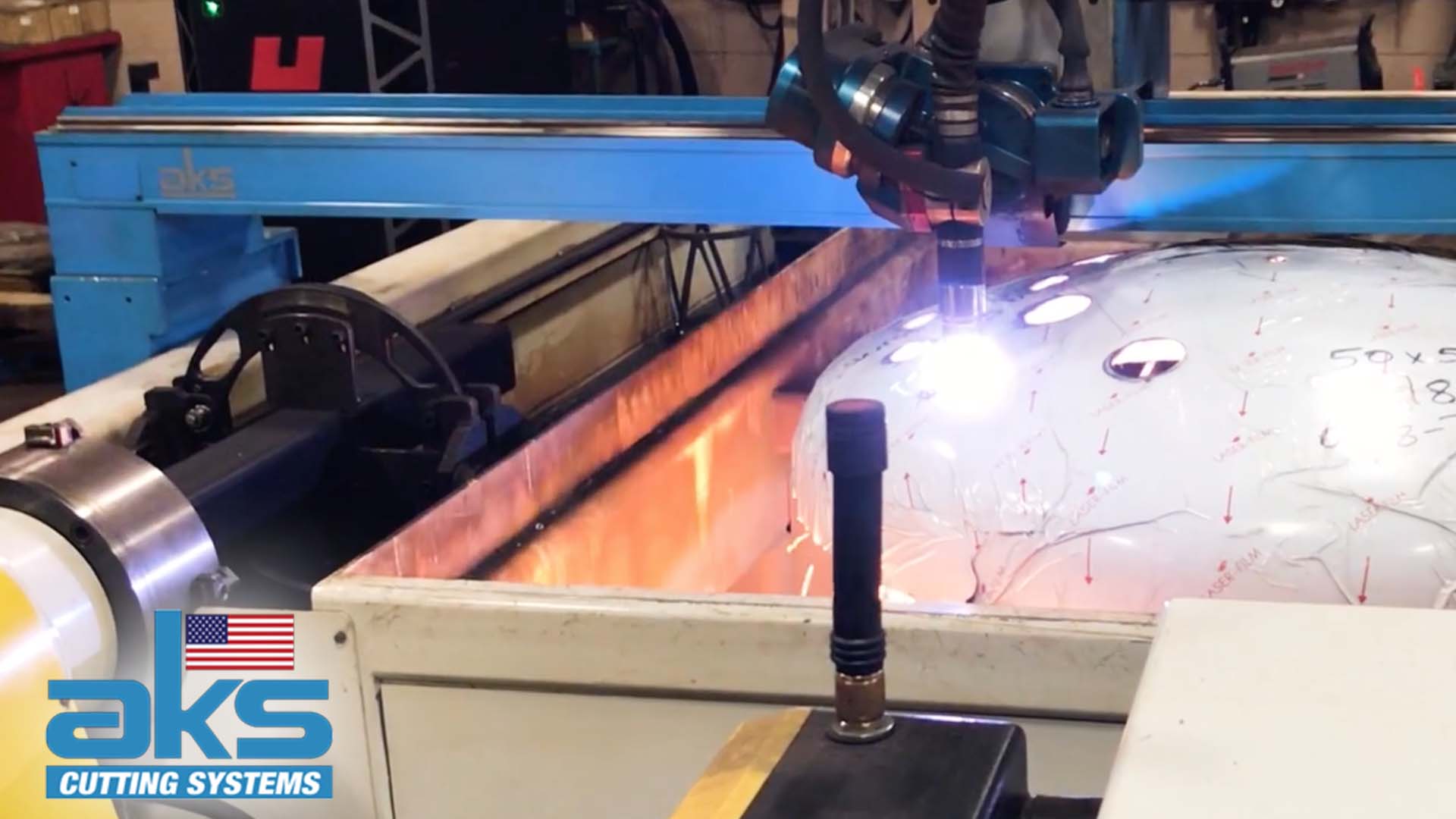

We’ve found that dome projects can be the most challenging application to cut on a plasma. However, thanks to advancements in cutting software and hardware configuration options over the past few years, it’s now feasible to cut domes and other 3D parts on a plasma table, provided you have 5-axis capabilities and a bevel head, or a robot with which to run your plasma torch. Five-axis robotic beveling, such as what you’ll find with an AKS robo-kut system, allows you to put bevels on domes and also lets you cut some geometries in formed domes.

Dome cutting is a specialized area that gets very technical very quickly. However, you can use the following tips to help guide you:

- Use the argon marking to scribe a crosshair on the top of the dome.

- Label the crosshair A, B, C, D or some ordinary valued amount, and cut everything relative to that crosshair, just on the right-hand side, rotating the dome 90 degrees with each cut.

- Next, use the crosshair to recenter and keep your programs square to each other, which allows you to access the whole diameter of the dome without having the collision issue. The idea is that as you remove slats, the pieces of material that run across the table support your cut piece.

- Open up the table to create space where you can put the dome in. As long as the top of the dome is underneath the bottom of the carriage or at the bottom of the bridge, it will fit.

What are Common Problems?

For best results, it’s important to be able to locate the center of the dome, which is a standard feature on AKS machinery. Also be sure your system allows you to apply hard offsets and hard points so you know where the dome is, and have programmable home positions. If your hard stops are removable, you can still cut plate. Then you could have a home position that checks where you think the center of the dome should be. The accuracy of the robo-kut is excellent in this capacity. Its lightweight design means no unwinding is necessary on the bevel head.

If you’re looking to cut domes all day, every day, consider overhead, robotic armatures that can reach around the whole dome effectively. Hypertherm has a separate branch of its business designed around the robotic integration of plasma cutting systems to robots – check out Robotmaster for details.

If you go to a system that has a tube-cutter and a bevel head, you can process nearly everything a standard weld shop touches in a year. Instead of having four separate systems – one to bevel, one to do layouts, one to do tubes or pipes and one to do plate – you can combine all of this functionality into one machine.

With an AKS system, you can get a one-stop-shop that allows you to approach this in a systematic way, allowing you to grow your business without a massive capital expenditure. That way, you’re only interacting with one company, and managing your jobs all with one product suite, as opposed to four to five different pieces of software and equipment that all have to be serviced separately.

Plasma cutting of domes can be challenging, but having the right tools can aid your shop’s production capabilities. To find out more, contact an AKS rep today.