Considering adding a plasma cutting machine to your operations? Here are some common questions we hear from our customers.

What percentage of plasma table buyers are first-time buyers? About 50 to 70 percent of plasmas are new or first-time AKS Cutting Systems buyers, with the remaining replacing existing machines. Often when replacing a plasma machine, the customer will be upgrading from an entry-level machine and wants better hole quality, 5-axis cutting or tube cutting.

What percent of plasma table buyers are replacement buyers (or second-time buyers)? Roughly one-third of our plasma table buyers are second-time or replacement machine buyers. Many are replacing a competitor table. Most are replacing tables that are between four and eight years old.

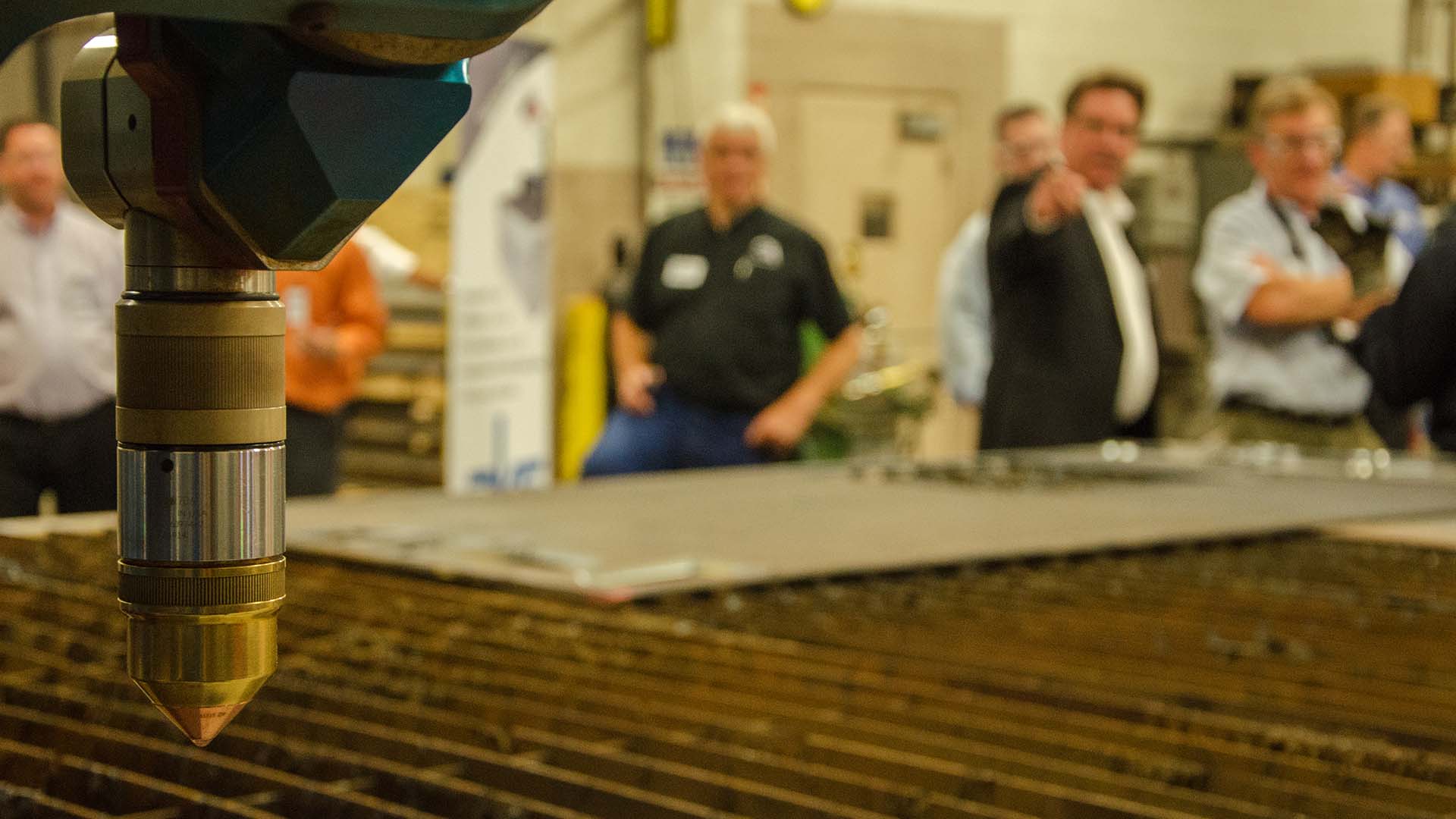

What percent of laser users also have a plasma table? We estimate roughly 15 percent have both lasers cutters and plasmas. Most customers with lasers are cutting thinner material and have a higher budget to invest in equipment. Many customers purchase an AKS plasma system because they get close to laser quality with a much lower investment cost. Some customers want the plasma to cut thicker materials and free up their laser to cut thinner, less intricate materials. Some customers with both are medium to larger shops that deal with larger agriculture customers or heavy equipment customers. At that point a larger plasma table is much more feasible than a larger laser, plus it can deal with the heavier plates such as 1-inch and thicker much more efficiently.

What is the average life cycle of an AKS plasma table? A non-AKS plasma table? The best part of an AKS plasma table is that our tables have a long life – if they are properly maintained – with an average life cycle of 10 to 20 years. For non-AKS tables, we’ve found the average life cycle to be anywhere from two to six years.

What software does AKS use? AKS plasma cutting systems use Hypertherm ProNest programming software.

What is the profile of a typical AKS customer? What type of shop buys your plasma cutters? The typical AKS customer is an established job shop of 10 to 40 employees, or limited product lines (farm equipment, trailers, construction equipment, mid-range steel supply houses, OEM support to aerospace, military, automotive, etc.) with revenue averaging approximately $10 million to $30 million. Some of them may already have cutting equipment (such as a waterjet) and want to increase their cutting speeds. More commonly, the customer is manually plasma cutting and wants to automate the process.

Typically, they’re cutting mild steel from ¼ inch to 1 inch. Most of our customers realize the importance of reliability and repeatability. They have demanding customers and need good equipment. They occasionally have the need for beveling as well and realize the advantage of our system. They all demand durability, superior cut quality, ease of operation, and company support to give them a competitive advantage over competitor products that require frequent repairs.

Why should I consider an AKS plasma cutter? AKS is a fourth-generation, family-owned and operated manufacturer of cutting machines. Since 1907, we’ve provided CNC cutting machines for thousands of satisfied customers, consistently delivering machines that are of the highest quality, performance, accuracy and durability in the market. [/vc_column_text][/vc_column][/vc_row]